- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Featured Posts

Innovation in Action: A Look Back at ATS LSS First E-Beam Sterilization Symposium

As we move into March, it’s time for a reality check—how are your New Year’s resolutions holding up? Many start the year with ambitious goals, but as time passes, priorities shift, and some resolutions start to slip. At ATS Life Sciences Systems, we believe that real progress isn’t about making resolutions once, it’s about maintaining them year-round. Just like personal resolutions, businesses must stay committed to their goals, whether that’s improving efficiency, reducing waste, or enhancing production quality. We don’t just set resolutions, we implement strategies that ensure measurable, sustainable success.

As we move into March, it’s time for a reality check—how are your New Year’s resolutions holding up? Many start the year with ambitious goals, but as time passes, priorities shift, and some resolutions start to slip. At ATS Life Sciences Systems, we believe that real progress isn’t about making resolutions once, it’s about maintaining them year-round. Just like personal resolutions, businesses must stay committed to their goals, whether that’s improving efficiency, reducing waste, or enhancing production quality. We don’t just set resolutions, we implement strategies that ensure measurable, sustainable success.

Choosing the Right Partner to Transform from Parts/Day to Parts/Minute Output – Centered on Ultra-Low Volume Dispensing in POC Diagnostic ManufacturingIntroduction Ultra-low volume dispensing for this discussion is the ability to dispense precise single droplets that are basically invisible to the human eye and defined in units of pico or nano liter volume. We care

Introduction Why are Innovations in Tube Set Manufacturing Important? Complicating the expected growth in demand in tube set markets, many suppliers are also experiencing a labor shortage due to the high operator counts (typically 150-200+ workers per shift to output at needed rates) and intense dexterity demands required of manual tube set assembly. In Mexico,

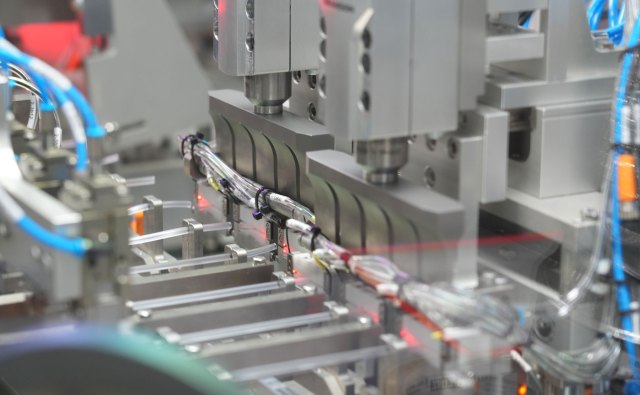

Flexible manufacturing platform Being built on the SuperTrak CONVEYANCE™ conveyance platform means that system modification and expansion is much simpler and cost effective. For example, should space be required to add additional tooling in order to manufacture a new product variant or increase capacity, the SuperTrak CONVEYANCE™ conveyance platform can be expanded by adding 1-meter

Introduction In the world of medical tube set manufacturing (IV, dialysis, blood collection, infusion), end users are not willing to pay top dollar for what is considered a ‘disposable’ piece of the process versus the pumps, therapies, plasma, etcetera. Therefore, it is imperative that production costs are minimized at the onset of a new product

Introduction When manufacturing medical tube sets, two of the most important factors to the manufacturer include output volume and product quality, both in terms of machine generated scrap (e.g. tube improperly inserted to connector and rejected by the machine) and product quality to the end user (e.g. no scuff marks on tubing, minimal particulate in

Introduction Why are Innovations in Tube Set Manufacturing Important? Complicating the expected growth in demand in tube set markets, many suppliers are also experiencing a labor shortage due to the high operator counts (typically 150-200+ workers per shift to output at needed rates) and intense dexterity demands required of manual tube set assembly. In Mexico,

25pL to 4.0uL dispensed discrete drop volume now capable in high output automation platforms According to a 2023 report, Global News Wire is reporting a 12.7% CAGR growth and greater than $80B USD in revenue by 2028 in Point of Care (POC) diagnostics. This tremendous growth is fueled by continuous glucose monitoring wearables, as well

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube