- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Tube Sets

Choosing the Right Partner to Transform from Parts/Day to Parts/Minute Output – Centered on Ultra-Low Volume Dispensing in POC Diagnostic ManufacturingIntroduction Ultra-low volume dispensing for this discussion is the ability to dispense precise single droplets that are basically invisible to the human eye and defined in units of pico or nano liter volume. We care

Andrew Glaser

Aug 6, 2024 • 8 min read

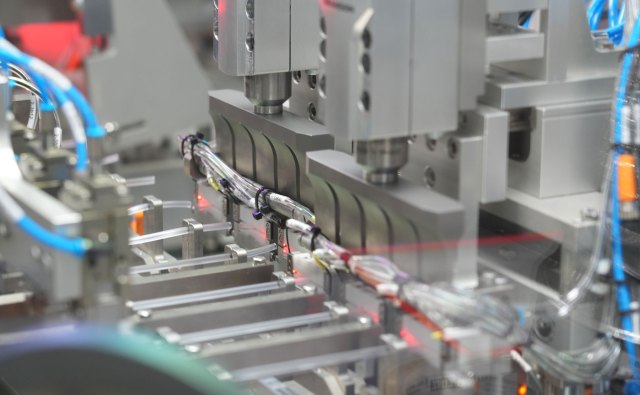

Introduction Why are Innovations in Tube Set Manufacturing Important? Complicating the expected growth in demand in tube set markets, many suppliers are also experiencing a labor shortage due to the high operator counts (typically 150-200+ workers per shift to output at needed rates) and intense dexterity demands required of manual tube set assembly. In Mexico,

Alex Folz

Jul 11, 2024 • 8 min read

Flexible manufacturing platform Being built on the SuperTrak CONVEYANCE™ conveyance platform means that system modification and expansion is much simpler and cost effective. For example, should space be required to add additional tooling in order to manufacture a new product variant or increase capacity, the SuperTrak CONVEYANCE™ conveyance platform can be expanded by adding 1-meter

Matt Park

Mar 28, 2024 • 5 min read

Introduction In the world of medical tube set manufacturing (IV, dialysis, blood collection, infusion), end users are not willing to pay top dollar for what is considered a ‘disposable’ piece of the process versus the pumps, therapies, plasma, etcetera. Therefore, it is imperative that production costs are minimized at the onset of a new product

Paul Nordin

Mar 27, 2024 • 4 min read

Introduction When manufacturing medical tube sets, two of the most important factors to the manufacturer include output volume and product quality, both in terms of machine generated scrap (e.g. tube improperly inserted to connector and rejected by the machine) and product quality to the end user (e.g. no scuff marks on tubing, minimal particulate in

Alex Folz

Mar 27, 2024 • 8 min read

Introduction Why are Innovations in Tube Set Manufacturing Important? Complicating the expected growth in demand in tube set markets, many suppliers are also experiencing a labor shortage due to the high operator counts (typically 150-200+ workers per shift to output at needed rates) and intense dexterity demands required of manual tube set assembly. In Mexico,

Alex Folz

Mar 13, 2024 • 8 min read

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube