- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Single-use, multiple-use or autodestruct syringes

SYRINGE ASSEMBLY

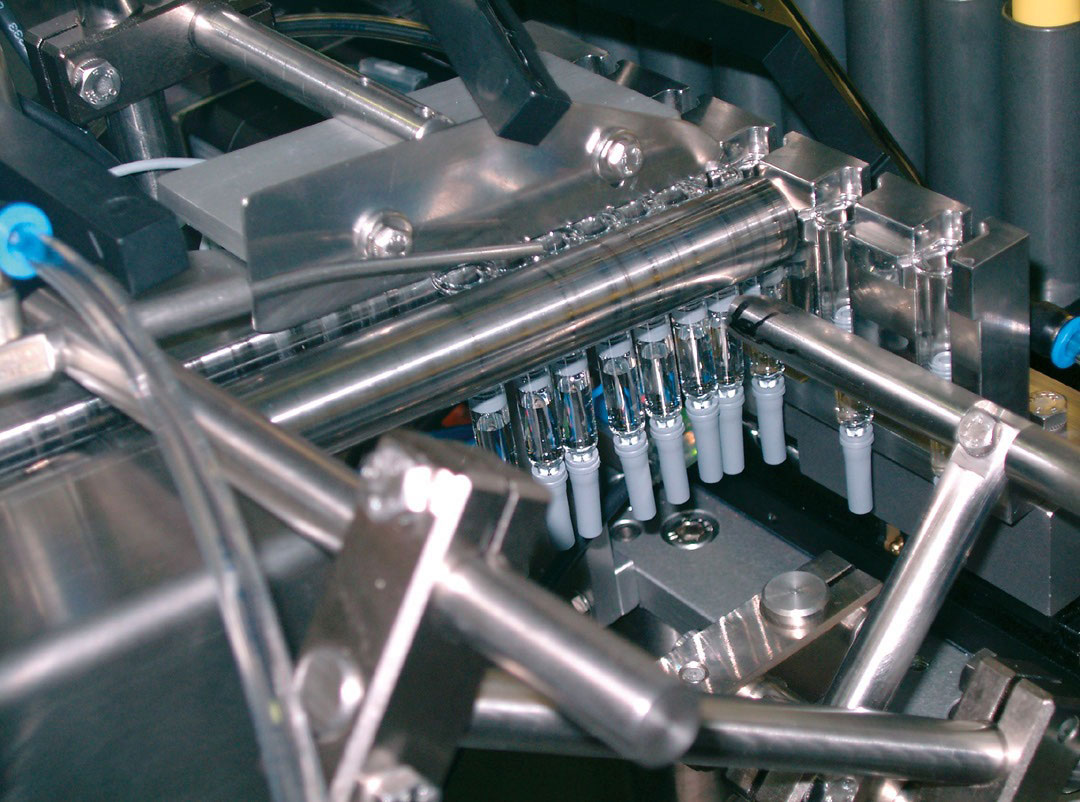

Specialization in the pre-assembly of glass syringes (glass barrel with cannula) and plastic syringes with cannula, as well as the final assembly of multi-component plastic syringes

Glass and Plastic Syringe Assembly

With many successful projects for the manufacture of syringes, including our unique patent for UV-adhesive curing, we are proud to call ourselves a global leader in this segment.

- Plastic assembly for autodestruct or retractable

- Glass assembly for cut or round flanges

- Gentle handling for the movement of components, subassemblies, and finished product, including stacked trays, pallets, bulk components, and more

Expertise

Glass Syringes

With many successful projects for the manufacture of glass syringes and our unique patent for UV-adhesive curing, our machines can handle different variations.

Plastic Syringes

Our machines cover pre-assembly of a plastic syringe with cannula, as well as the final assembly of multiple components.

Autoinjectors

Automated pre- and final assembly of self-administered disposable drug delivery systems.

Looking for a standardized platform, or ready to explore the potential of a customized option?

We deliver proven solutions to ramp up your syringe manufacturing for short-term results, or work with you to develop a fully custom line

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube