- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Managing for success

PROJECT MANAGEMENT

Successful execution is, in part, a result of focus on project management discipline. You can count on us to support your project delivery needs until final signoff at your installation site.

Managing for success

Our highly skilled and experienced project managers have a proven track record of successfully delivering complex programs including:

- Planning and coordinating all tasks and securing necessary resources

- Mitigating risk

- Monitoring, navigating, and iterating to accommodate dynamic project conditions

- Maintaining open, respectful, and collaborative lines of communication

Engineering

In a regulated environment, complying with good manufacturing practices is essential requiring rigour and discipline. We’ve built this same focus into our engineering processes as a complement to your regulatory processes and needs.

///We consult with you to identify critical-to-quality attributes so we know where to focus our GMP efforts

///We build and maintain a trace matrix to document the evolution from your user requirements to final testing, including validation

///We design our solutions to meet your GMP needs and outline them in a basis of design document before design begins

///We partner with you through a rigorous design review process, and all requests and actions are formally recorded and closed

///We follow a formal change control procedure to appropriately document, review, and approve requests

///We test to confirm that the function satisfies the design intent as we integrate your system’s various elements

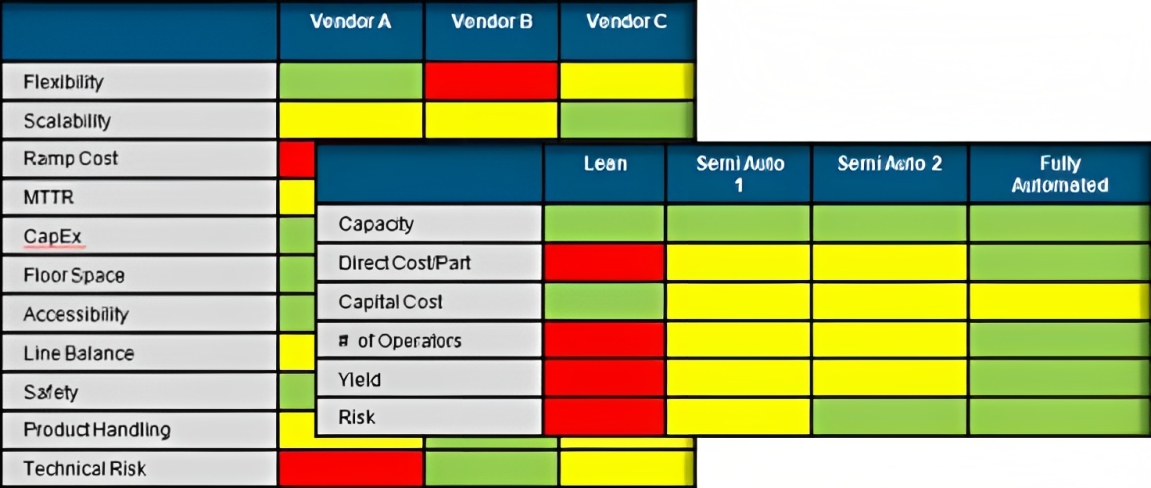

Procurement

PURCHASING POWER

We have a performance-driven, vertically integrated supply chain with a global presence. Our end-to-end capabilities include:

///dedicated supplier management,

///value engineering,

///value analysis services.

Our vendor pre-selection program, auditing system, and annual report cards help ensure we are working with reputable, reliable, and responsible supplier partners.

What does this mean for your project? With multifaceted automation market experience, we are able to source the right products at the right prices in the right geographical area for your immediate project and operational needs, and then for your post-installation maintenance and upkeep needs.

Assembly & Integration

TRANSLATING THE CONCEPT INTO REALITY

Fabrication, assembly, and integration of every system is the science of what we do. The art is in the application of our experience, built over thousands of projects, to the fine-tuning and installation of your final product. Our engineers elevate what might otherwise be an ordinary machine into a superior solution.

Testing & Validation

THE PROOF IS IN THE TESTING

From commissioning and qualification planning to final reports, we will work closely with you and your team to understand your specific regulatory environment and deliver a fully compliant system. This includes the preparation and execution of factory and site acceptance (FAT, SAT) test protocols, installation and operation qualification protocols, and trace matrices, using our own pre-established templates or yours.

Once testing is complete, you will have the necessary objective evidence to prove your user requirements have been met.

Other Services

Pre-automation Services

Feeling confident about your capital investment plans begins with thorough evaluation and planning. A business investment strategy can set you on the road to capitalizing on opportunities.

Post Automation

Our commitment to providing world-class systems extends to service and technical support. We have a full menu of post-automation services to keep your operation running smoothly.

Contract Manufacturing

Turnkey repetitive equipment manufacturing (REM) and build-to-print services apply value engineering and supply chain cost reductions to help you meet your demand forecast efficiently.

Planning for Success

Working with our project management team, you can be confident we will internalize and own your requirements, advocate for your project, and strive for an exceptional project outcome.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube