- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

At-a-glance data on your carbon footprint

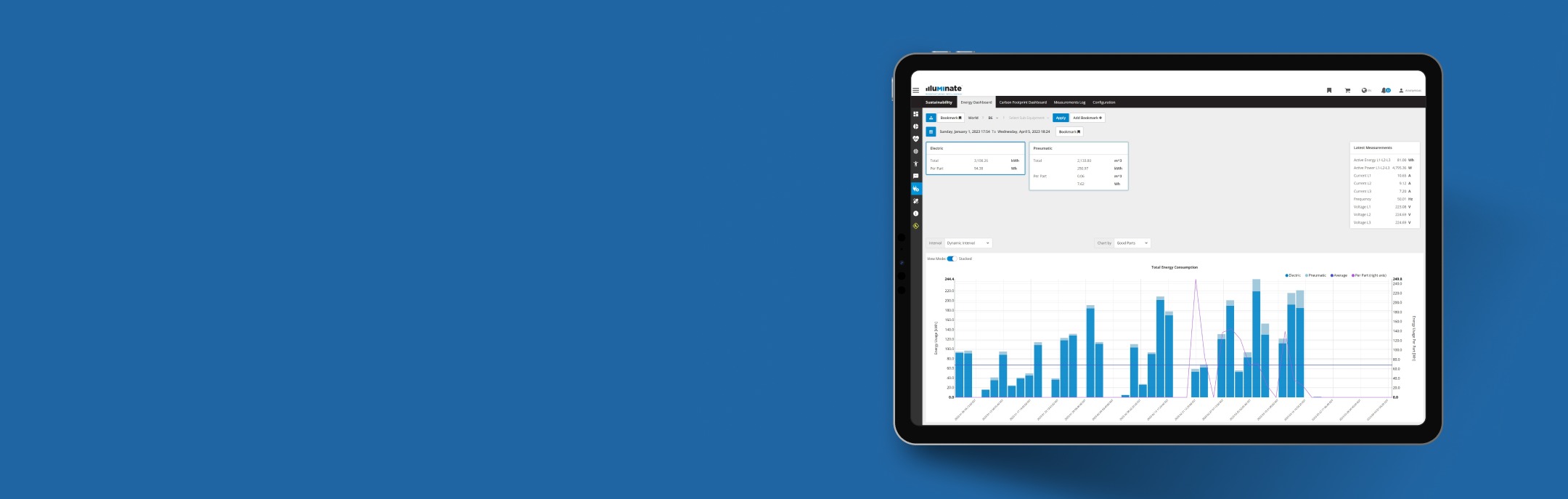

ILLUMINATE™ ENERGY AND EMISSIONS ADD-ON MODULE

Make informed decisions to mitigate the environmental impact of manufacturing processes with real-time visibility to your plant’s energy consumption and CO2e emissions

“At the moment we need weeks of time to calculate energy consumption per part to show our cost structure to our customers. Illuminate has this information with one click. Unbelievable!”

– Manufacturer of injection and infusion systems

Insights to help improve sustainability in operations

- Energy Dashboard: Pneumatic and electrical energy consumption, over any time-period to reduce energy usage

- Carbon Footprint Dashboard: Gain insights on the overall CO2e emissions in your operations at the part, machine and factory level

- Measurement Log: View machine spikes and deviations in active energy, frequency, voltage, and power

- Configuration: Configure and edit C02 coefficient by your country or region

Key Benefits

Make data driven decisions to reduce energy and C02e emissions.

Understand C02e emissions across the factory floor

Understand C02e emissions across the factory floor

At-a-glance production-related data with granular level details on per part and per machine energy consumption and emissions while in operation. This highly scalable solution measures single stations, machine zones, and whole automation systems

Identify trends in your carbon footprint

Identify trends in your carbon footprint

Use the module’s stacked and grouped reporting to understand daily, monthly, and yearly trends. With increasing pressures from regulators, and the impacts of carbon emissions on the environment, working toward net zero emissions has become a competitive edge and business imperative

Control costs while demonstrating accountability

Control costs while demonstrating accountability

Save costs and use less resources including time spent to generate and collect data on energy consumption and C02e emissions. Easily export results to share with colleagues for planning ESG initiatives and use for annual sustainability reporting

Actionable insights

Actionable insights

Use the module’s capabilities to produce unique data, like insights on reject scrap rate to identify ways to reduce C02e emissions. Also, view and understand the C02 impact of single parts on your overall carbon footprint

Other Vision & Testing

ATS PharmaScan™ Platforms for Advanced Inspection

The PharmaScan™ family of advanced inspection platforms is designed to meet the highest pharmaceutical industry standards for liquid or lyo. Check for multiple defect criteria.

ATS SmartVision™& ATS Cortex™ Solution

Vision system and open software for the coordination and control of cameras and lighting systems necessary for complex inspections, offering cost-effectiveness, connectivity, and customization

Bluetooth® Connected Devices Functionality Test

A test system that verifies and validates the correct transmission of data and functionality of your Bluetooth® enabled smart medical and diagnostic devices, which can be a stand-alone solution or an integration into existing automation

Take control of your energy consumption and C02e emissions today!

Make informed decisions on sustainability in your operations with real-time data at your fingertips. Use the insights provided by this easy-to-use software to demonstrate action and accountability.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube