- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Specialty operations for automated manufacturing

SPECIALTY MANUFACTURING PROCESSES

Manufacturing processes can be highly complex. You have high quality standards to comply with GMP requirements and deliver safe products to the marketplace. The assurance of product quality and a robust supply chain are critical to success.

Process Capabilities

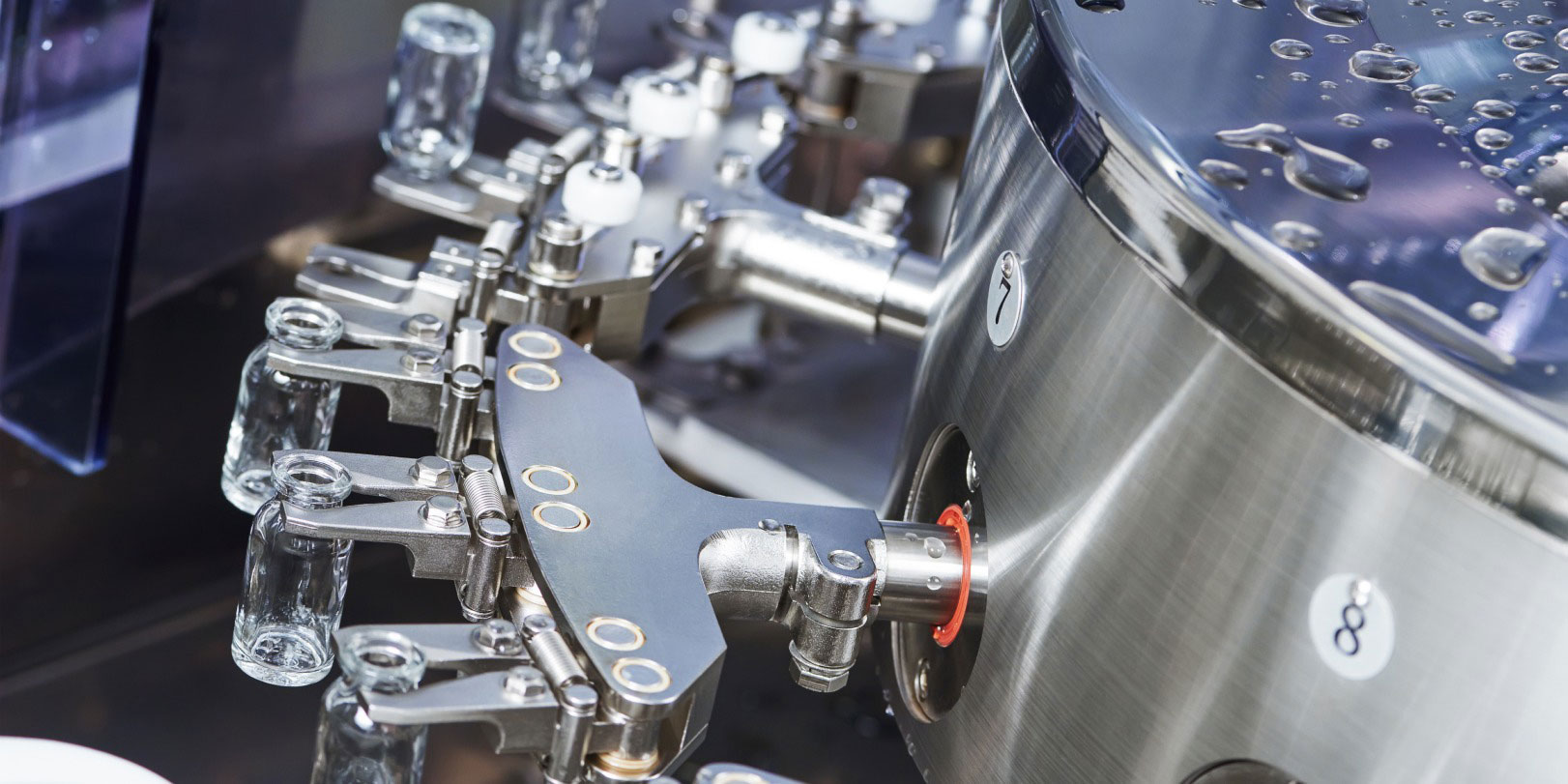

Handling

Material handling for the movement of components, subassemblies, and finished product, including component logistics, feeding, pre-treatment, and quality control. Solutions for stacked trays, pallets, bulk components, and more.

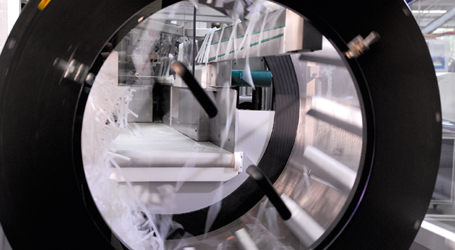

Manufacturing

So many combinations of processes can be involved in the manufacture of your product. We meet your requirements for fluids-based processes, forming, component manipulations, attaching, fastening, and bonding – laser, ultrasonic, adhesive.

Testing

From smart sensors to measurement systems, we deploy the appropriate checks and verifications to validate the operating environment, process steps, and in-process and finished product. Vision systems, real-time data, in-process product samples.

End of Line

Finished products may be placed into trays, clam shells, blisters, tubs, or pouches, and then further packaging as kits, tubs or multi-pocket trays before labeling and cartoning. Disinfecting, palletizing and AMR solutions complete the line.

Specialty Processes for Your Manufacturing Automation

Our products and services support the entire manufacturing process from material intake to finished and packaged product. Whether you require a customized system, a standard piece of equipment, or a fully integrated production line, we can help.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube