- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Business solutions tailored to your needs

PRE-AUTOMATION SERVICES

A successful automation is more than just a machine. ATS is a single source systems integrator and enterprise solution provider, bringing cohesion, consistency and accountability to a program.

Business Solutions

Feeling confident about your capital investment plans begins with thorough evaluation and planning.

- Manufacturing concept development and evaluation

- Simulation

- Prototyping

- Product and process development support

- Proof of principles studies

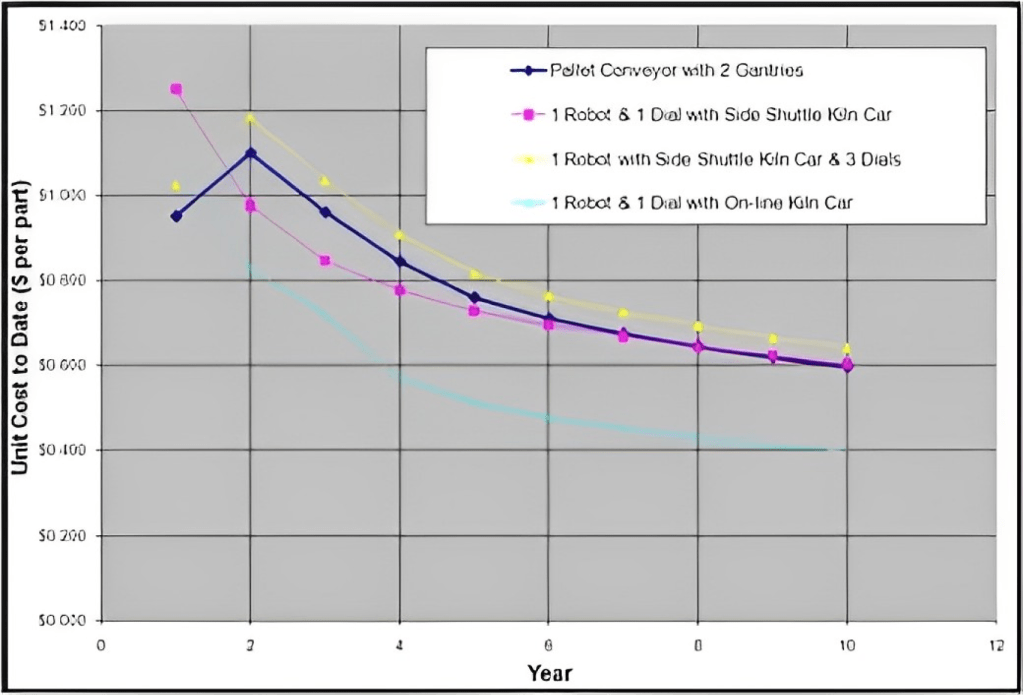

- Total Cost of Ownership (TCO) analysis

- CGMP review

- Validation

Proof of Principle

The proof is in the testing. From commissioning and qualification planning to final reports, we will work closely with you and your team to understand your unique regulatory environment and deliver a fully compliant system. This includes:

///The preparation and execution of factory and site acceptance test protocols

///Installation and operation qualification protocols and trace matrices

///Using our own pre-established templates or yours.

Once testing is complete, you will have the necessary objective evidence to prove your user requirements have been met.

Process Development

Our project teams are frequently asked to solve automation problems that haven’t been solved before. Starting with an understanding of clear requirements, we leverage our technology expertise and product assembly, inspection, and testing know-how to inform our ideas, and construct and demonstrate a conceptual solution. To gain confidence, our team of technical experts, staff scientists, and suppliers draw on our previous experience to do the following and more:

///Design proof-of-principle studies

///Specify prototypes

///Execute design of experiments

///Perform repeatability and reproducibility testing

Risk Management

As a project progresses, the ease of making a change decreases and the cost associated with the change often increases. This is because as time passes, there is more invested and change means discarding, redoing, or adding to at least some of what has been executed.

The skill is to identify risk early and mitigate it quickly. Our experienced team will help you put plans in place to acknowledge and avoid significant risks to the project and the timeline.

Other Services

Project Management

Our highly skilled PMs have a track record of successfully delivering complex programs by setting the course, defining success parameters, and nurturing relationships for the duration.

Post Automation

Our commitment to providing world-class systems extends to service and technical support. We have a full menu of post-automation services to keep your operation running smoothly.

Contract Manufacturing

Turnkey repetitive equipment manufacturing (REM) and build-to-print services apply value engineering and supply chain cost reductions to help you meet your demand forecast efficiently.

Business Planning for Success

Pre-automation planning identifies possible courses of action and results in a business investment strategy that can set you on the road to being best-in-class. You tell us what you need; we’ll propose the matching service offering.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube