- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

All-in-one integrated vision system

ATS CORTEX NEO

Vision system and open software for the coordination and control of cameras and lighting systems necessary for complex inspections, offering cost-effectiveness, connectivity, and customization

ATS Cortex NEO

Reduce integration time with a vision solution that comes complete with standardized hardware and software.

- Scalable across application types and levels of complexity

- Powerful toolkit included

- Rapid application development

Key Benefits

An integrated vision solution that comes complete with standardized hardware and software.

Processing Computer

Processing Computer

Can communicate with a Programmable Logic Controller (PLC) through a wide variety of field bus interfaces.

Flexible Storage

Flexible Storage

Varying levels of storage and RAM by model configuration to suit any application.

Camera Power

Camera Power

Can connect to a maximum of four (4) GigE Power Over Ethernet (PoE) cameras.

Plug and Play

Plug and Play

The USB connectors are standard USB 3.1 plug and play connectors used for the integrated backup device and other peripherals such as a keyboard and mouse.

Other Vision and Testing

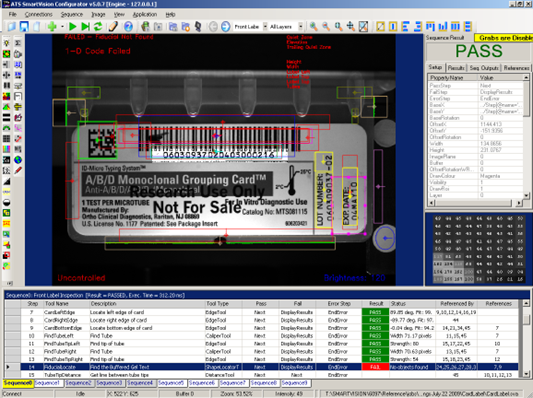

SmartVision™

SmartVision software is a highly scalable PC-based vision system that combines a high-performance, platform-independent vision engine with an easy-to-use development interface.

PharmaScan™

The PharmaScan™ family of advanced inspection platforms is designed to meet the highest pharmaceutical industry standards for liquid or lyo. Check for multiple defect criteria.

Bluetooth®

Verify and validate the correct transmission of data and functionality of your Bluetooth® enabled smart medical and diagnostic devices. We co-develop Bluetooth® functionality tests tailored to your specific product and process requirements.

All-in-one Integrated Vision System

For complex inspections, we offer cost-effectiveness, connectivity, and customization. Let’s see what we can put together!

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube