- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

End-to-end expertise from handling to manufacturing to testing to packaging

HANDLING PROCESSES

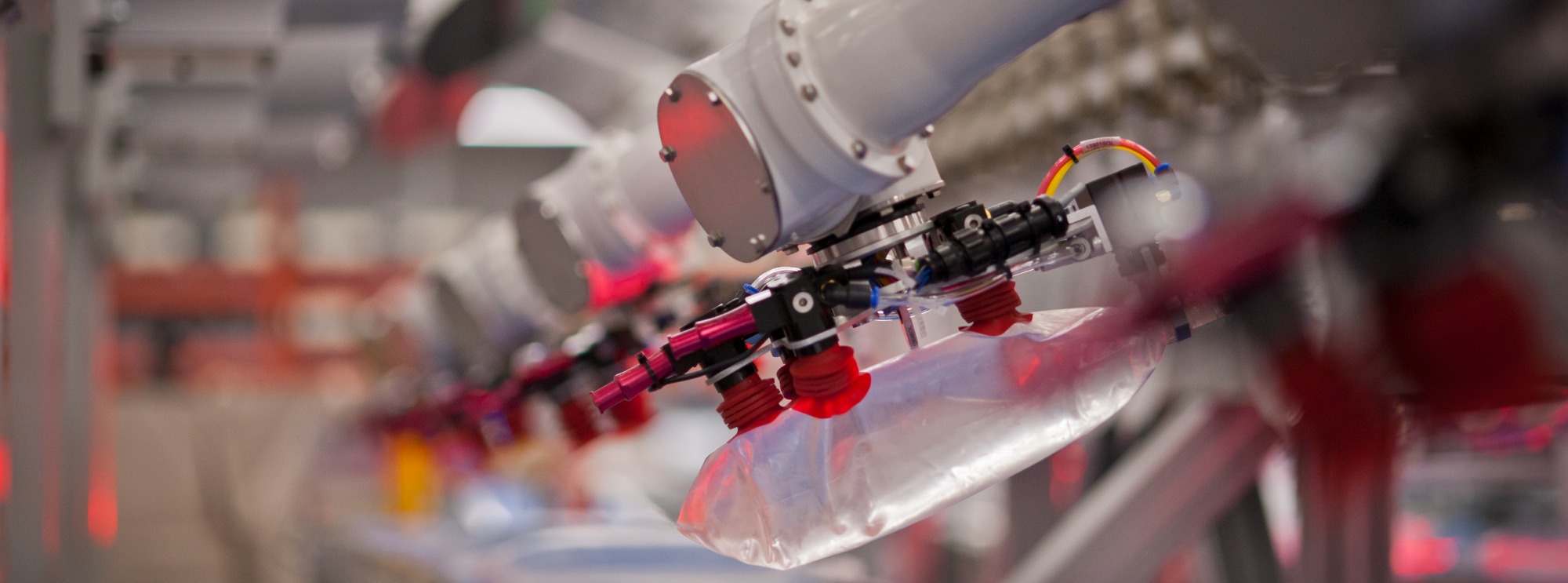

Robot-assisted or fully automated systems for material handling of parts, components, trays or pallets. Improve capacity, safety and precision from feeding to assembly to labeling to finished product

Specialty Handling Processes

Conveyance

High-speed part transfer systems for cleanrooms or aseptic processes; intelligently integrated to link handling systems for downstream stages of assembly.

✕

High-speed part transfer systems for cleanrooms or aseptic processes; intelligently integrated to link handling systems for downstream stages of assembly.

Learn More

Feeder Technology

Designs for reliable feeding and orientation of small or lightweight parts; particularly effective for safely transporting small, unstable parts that cannot be fed in bulk.

✕

Designs for reliable feeding and orientation of small or lightweight parts; particularly effective for safely transporting small, unstable parts that cannot be fed in bulk.

Contact Us

Trayhandling

Process automation is made possible with flexible gripping and precision handling of parts by robots. Customized turnkey systems for bin picking and assembly for sterile and non-sterile applications.

✕

Process automation is made possible with flexible gripping and precision handling of parts by robots. Customized turnkey systems for bin picking and assembly for sterile and non-sterile applications.

Learn More

Dispensing

Automated, high-throughput, ultra-low volume dispensing from pico liters to nano liters (ml, ul, pl). IV bags, flexible, aseptic, infusion, combo, poly, dual chamber, and cryogenic bags for cell and gene therapy. Highly accurate and reproducible, vital to consistently high standards of production.

✕

Automated, high-throughput, ultra-low volume dispensing from pico liters to nano liters (ml, ul, pl). IV bags, flexible, aseptic, infusion, combo, poly, dual chamber, and cryogenic bags for cell and gene therapy. Highly accurate and reproducible, vital to consistently high standards of production.

Contact Us

Marking

Various printing technologies (inkjet, pad printing, laser, thermal transfer) for marking on a variety of materials. Some methods support multiple colors and can guarantee accurate positioning of the product for consistent machine-readable results.

✕

Various printing technologies (inkjet, pad printing, laser, thermal transfer) for marking on a variety of materials. Some methods support multiple colors and can guarantee accurate positioning of the product for consistent machine-readable results.

Learn More

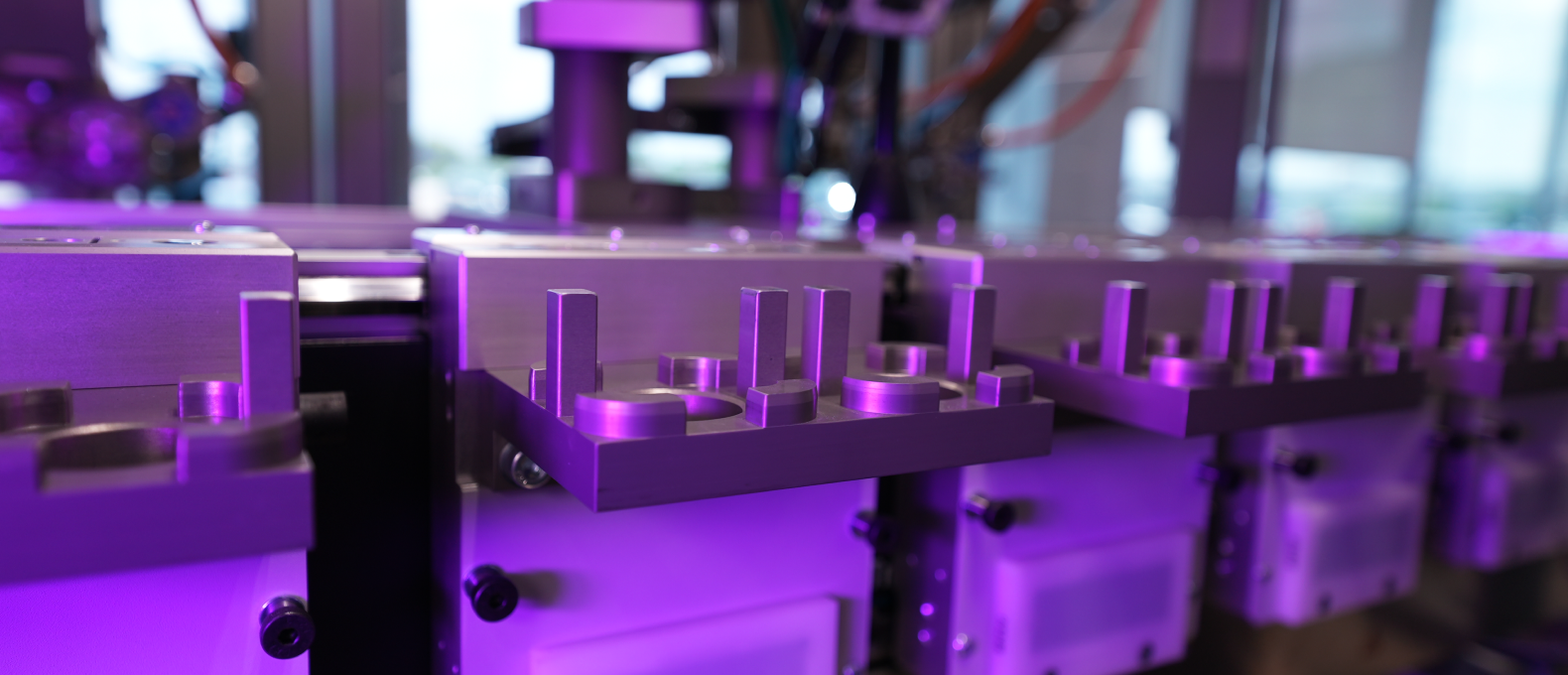

Filter and Foil

Automated systems for de-reeling filter or foil materials through punch/die sets (Feeding and Punch). Punching dies are interchangeable. Custom specifications to meet customer requirements.

✕

Automated systems for de-reeling filter or foil materials through punch/die sets (Feeding and Punch). Punching dies are interchangeable. Custom specifications to meet customer requirements.

Learn More

Cleaning

Tubes are washed (Ultrasonic, Plasma, Chemical Bath, CO2) in a closed-cycle chamber, with up to 80% of water being returned. For purity, multistage filtering technology, capable of removing particles 0.2 μm in size. Can be followed by siliconization. Tubes are dried at a controlled temperature

✕

Tubes are washed (Ultrasonic, Plasma, Chemical Bath, CO2) in a closed-cycle chamber, with up to 80% of water being returned. For purity, multistage filtering technology, capable of removing particles 0.2 μm in size. Can be followed by siliconization. Tubes are dried at a controlled temperature

Learn More

API Handling

Mitigate the risk of microbiological contamination and product adulteration (Lyo, Powder, Reagent), while protecting the operator. Isolators and automated processing create a safe, aseptic environment that maintains separation between product and people.

✕

Mitigate the risk of microbiological contamination and product adulteration (Lyo, Powder, Reagent), while protecting the operator. Isolators and automated processing create a safe, aseptic environment that maintains separation between product and people.

Learn More

Mold Tending

Custom, high-speed robot solutions provide flexibility for material handling. Designed to optimize system layout, part transfers happen within a multiple shot mold or between multiple machines.

✕

Custom, high-speed robot solutions provide flexibility for material handling. Designed to optimize system layout, part transfers happen within a multiple shot mold or between multiple machines.

Learn More

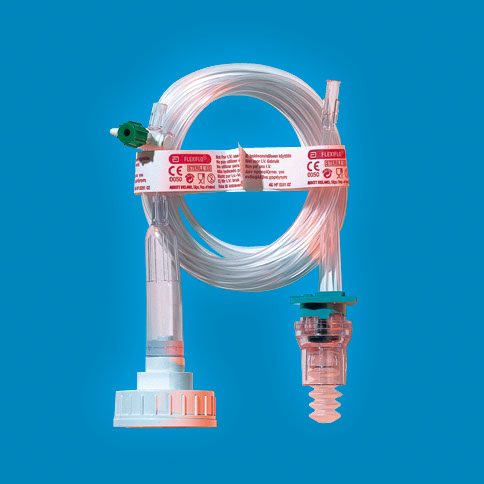

Tube Handling

ATS has standard assembly machines for medical devices that require tube handling and joining (example tube sets)

✕

ATS has standard assembly machines for medical devices that require tube handling and joining (example tube sets)

Learn More

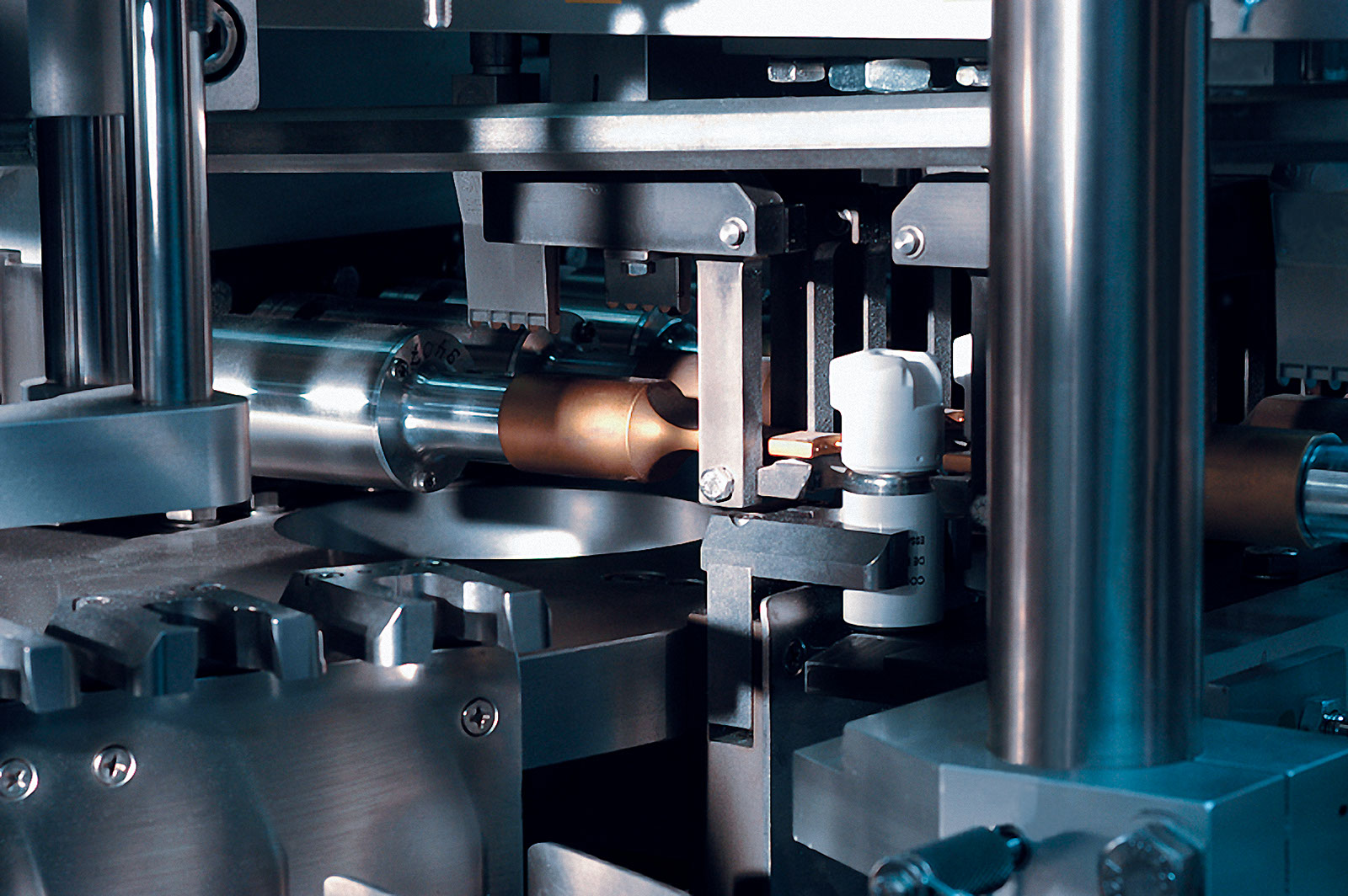

Cannula Handling

Injection products, such as safety syringes and IV catheters, must be precision manufactured. Tip forming comprises precisely shaping the tube around the cannula. The correctly-oriented needle is directly transferred to the cannula hub for maximum precision.

✕

Injection products, such as safety syringes and IV catheters, must be precision manufactured. Tip forming comprises precisely shaping the tube around the cannula. The correctly-oriented needle is directly transferred to the cannula hub for maximum precision.

Learn MoreLet’s get your product moving

ATS provides specialty handling capabilities for your life science automated manufacturing. Backed by decades of experience, we can suggest standardized machines or work with you to develop a custom solutions

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube