Asset management and post-project services

POST AUTOMATION

The strong loyalty of our customers is a result of the systems supplied AND our commitment to providing world-class service and technical support.

Your life cycle service partner

From ramp-up to decommissioning, ATS has solutions and technologies that are designed to help predict, identify and resolve issues before they happen, and achieve higher, sustained operational performance.

Maintenance and support

Spare parts and repairs

Retooling and upgrades

Lifecycle extension

Total plant performance

Maximize asset performance with proactive support

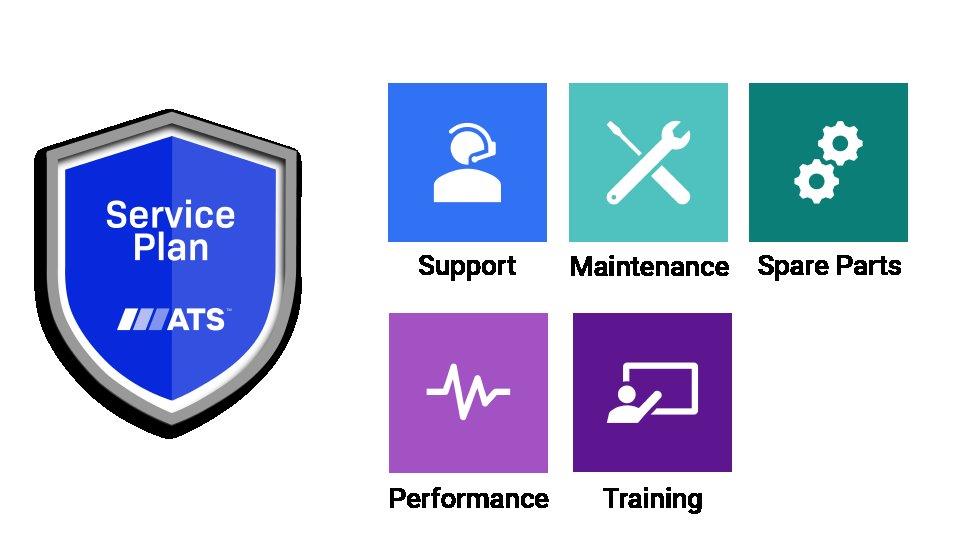

ATS Lifecycle Service Plans support operational excellence through proactive maintenance practices and expert support. Our service plans can be designed to provide:

Access to ATS expert support

Maintenance program optimization

Parts inventory and obsolescence risk management

Greater visibility to machine health and production issues

Operation and maintenance training, and more!

Optimize your asset management strategy

Increase uptime, throughput, availability, and performance, and free up your maintenance team to focus on high value work by optimizing your maintenance and reliability strategies.

Using risk-based, data-driven solutions, Triad Unlimited, ATS Reliability Center of Excellence, can support individual projects to full program implementations for aging and undeveloped sites around the world.

Global service, local presence

Our service network is made up of different facilities, teams, and service professionals, each with their own unique capabilities, expertise, and industry experience.

Positioning ourselves closer to our customers enables faster response times and better support during scheduled maintenance activities and unplanned downtime events.

Other Services

Pre-automation Services

Feeling confident about your capital investment plans begins with thorough evaluation and planning. A business investment strategy can set you on the road to capitalizing on opportunities.

Project Management

Our highly skilled PMs have a track record of successfully delivering complex programs by setting the course, defining success parameters, and nurturing relationships for the duration.

Contract Manufacturing

Turnkey repetitive equipment manufacturing (REM) and build-to-print services apply value engineering and supply chain cost reductions to help you meet your demand forecast efficiently.

Mix and Match Offerings for Customized Support

Combine service offerings to address your specific needs so you can reach your targets more quickly, an approach that could save you time and money. Let’s discuss how to optimize your investment.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube