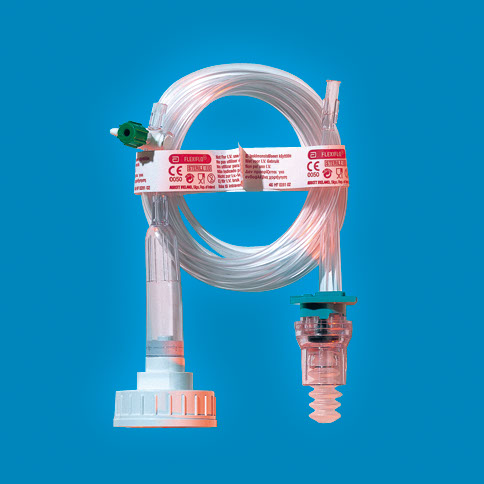

Medical tube-sets used in procedures such as infusion, transfusion and dialysis are an integral part of modern healthcare. Highspeed automated tube set assembly systems like those manufactured by ATS Life Sciences Systems (LSS) are critical to meeting the global demand for high-quality, low-cost tube sets.

Flexible manufacturing platform

ATS LSS tube set assembly systems are highly configurable, and can be designed to produce simple, 6” tail segments to extremely complex, multi-segment tube sets with 10+ components and multiple coils.

A typical assembly rate for tail (single, straight segment) machines is up to 60 cycles per minute. The most common configuration of these types of machines is a two-track system but more tracks and/or stations can be added for a gross total output of 180 parts per minute.

Being built on the SuperTrak CONVEYANCE™ conveyance platform means that system modification and expansion is much simpler and cost effective. For example, should space be required to add additional tooling in order to manufacture a new product variant or increase capacity, the SuperTrak CONVEYANCE™ conveyance platform can be expanded by adding 1-meter modules.

Designed for maintenance and reliability

ATS has been manufacturing tube set assembly systems for more than 40 years. In fact, some of the systems delivered 20 years ago are still in operation today. With proper operation and maintenance, these systems can remain in operation for years with minimal downtime and performance degradation, thereby maximizing return on invested capital.

LSS tube set assembly systems are built using proven technology and certified parts sourced from the world’s top suppliers; partners that share our commitment to quality and performance. This increases system reliability and makes it easier to source replacement parts.

Maintenace requirements are also factored into the design of every tube set assembly system. For example, mounting tooling inboard of the SuperTrak CONVEYANCE™ conveyance loop makes it more accessible when components need to be inspected, calibrated or replaced.

Earlier generations of tube set assembly systems utilized cam driven tooling. This made it difficult and time-consuming to make adjustments and perform maintenance tasks, particularly on process heavy stations, such as tube set component insertion.

The latest assembly systems are anchored on an asynchronous chassis (SuperTrak CONVEYANCE™ platform) and utilize synchronous, servo-pneumatic station tooling which can be modified electronically, eliminating the need for difficult, time-consuming mechanical adjustment.

In some instances, automatic adjustments can be pre-programmed, such as the forward and back travel of a servo. When using a pneumatic gripper, the compliance inherent in pneumatic gripping mechanisms enables our tooling to easily handle tubing with different geometries – when the tube gets smaller, the grippers simply close a little more. This entirely eliminates the need for an operator or technician to adjust settings in the HMI.

Faster integration and better performance

Tube set assembly systems built on the SuperTrak CONVEYANCE™ conveyance platform have multiple advantages over cam driven systems. These include operational factors like the elimination of solvent timeouts (due to unlinking station timing from one another), consistent tube pull length, and insertion stations that can adapt to incoming product variance (e.g. changes in the diameter of tubing).

They generally also incorporate less tooling and fewer mechanical components which tends to speed up the design cycle and integration, meaning faster time to production. Furthermore, the overall technology envelope is much better aligned to the skillset of today’s labor force (computer literacy versus mechanical literacy), reducing the effort required to find skilled operators and technicians.

ATS can develop a customized onboarding package with the information and training needed to operate and maintain your tube set assembly system to its highest level of performance.

The standard ATS onboarding package includes an Operation and Maintenance Manual (OMM) and in-person instruction during acceptance testing and integration.

Maximize asset performance with proactive support

No two automated manufacturing systems are alike, and neither are the needs of manufacturers when it comes to post-integration support. ATS Lifecycle Service Plans are tailored to meet the unique needs of your manufacturing operations, whether you are new to automation or taking delivery of your latest tube set assembly system built on the SuperTrak CONVEYANCE™ conveyance platform.

ATS Lifecycle Service Plans help manufacturers identify and manage risks and increase operational performance. They also promote proactive maintenance practices that lower total cost of ownership.

Our services plans can be designed to provide:

- Access to ATS expert support

- Maintenance program optimization

- Parts inventory and obsolescence risk management

- Greater visibility to machine health and production issues

- Operation and maintenance training, and more!

Need additional ATS support during Year One operations? Our Startup Service Plan is an integrated service program designed to reinforce critical operating guidelines and maintenance procedures and accelerate problem resolution during production ramp-up.

Unscheduled downtime becoming an issue? ATS can design a Lifecycle Service Plan to help you meet daily production targets and improve specific aspects of overall operational performance such as safety, quality, delivery, and cost.

For more information about ATS Lifecycle Service Plans visit ats-service.com. To learn more about LSS tube set assembly, visit the website.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube