- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Synchronous Cam Drive Linear Assembly

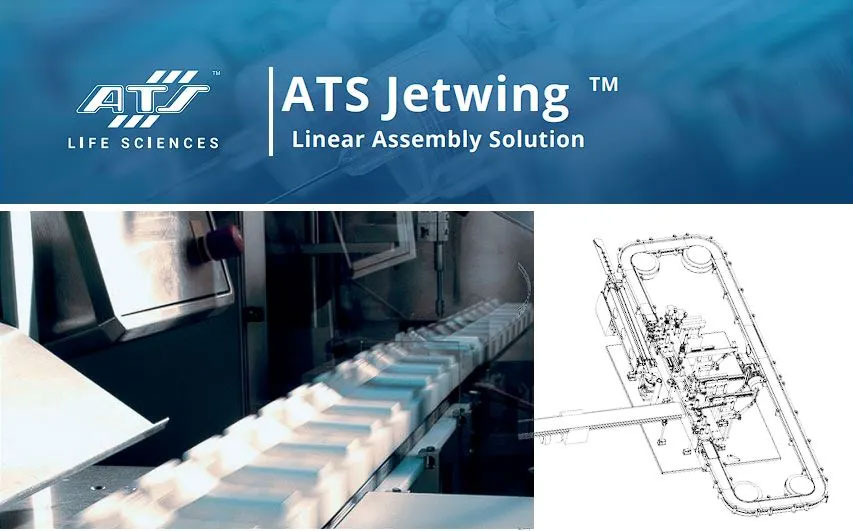

ATS JETWING™

High speed, modular system for semi- and fully-automated assembly for product development, pilot, and production purposes. An exceptionally versatile, compact, linear assembly platform.

ATS JETWING™

Based on standard modules that can be easily combined for a tailored assembly line, making you more responsive to changing market demand

- Optionally for cleanrooms up to Class 8

- Customization options such as manual workstations, feeder units or tray handlers

- Perfect for manufacturing high volumes of items with short lifecycles

OVERVIEW

SPECS

Features

- Quick retooling of stations to accommodate new products or variants

- Quick retools, combinations of stations via interfaces, introduction of new stations/modules or product changes

- Can be combined with manual workstations

Applications

- Ideal for products with a small number of parts, or ones still under development

- Reusable: Individual functions can be replaced

- Ideal for the product development phase and assembling large quantities of products with short lifecycles

Recommended For

- Specially developed for assembling items that need to go into production quickly or require frequent design change

- Pumps, tube sets, blood collection, syringes, inhalers, and other medical devices

- Multiple-track assembly possible

Specs

- Base system dimensions: 1120 x 1540 x 2300mm

- Number of stations: up to 16

- Number of Tracks: multiple-track assembly possible

- Synchronous cam drive linear assembly

- Cycle speed: infinitely variable, up to 80 cycles per minute

- Cleanrooms: Suitable up to class 10,000 / ISO 7

- Optionally for cleanrooms up to Class 8

- Output rates up to 80 ppm (depending on product)

- Can also be configured with pneumatic and/or linear motion technology

- Positional accuracy: +/- 0.02 mm

- Pallet sizing: 100 x 100 and 200 x 100 mm

- Modular design; twin drive; short lead times and rapid retooling

Key Benefits

Exceptionally Versatile

Exceptionally Versatile

Quick retooling of stations to accommodate new products or variants. Perfect for manufacturing high volumes of items with short lifecycles, and for both semi- and fully-automated assembly.

The Right Drive

The Right Drive

Jetwing is equipped with a twin drive, comprising a cam drive for the stations with a servomotor-powered spindle drive for trays. The pallets are mechanically indexed forward on the assembly platform, and returned via a conveyor belt.

Modular

Modular

Connect the standard platform, functional stations, test/inspection and transfer modules via standard interfaces to create an end-to-end solution. Stations can be quickly retooled for new products or variants.

Customizable

Customizable

A wide variety of customization options such as manual workstations, feeder units or a tray handler. Interlink up to six Jetwings to handle even very complex tasks. All process technologies and testing systems can be integrated, such as vision systems and tests for leakage and back pressure.

Resources

BROCHURE

ATS JETWING™ – Linear Assembly Solution

Jetwing was specially developed for assembling items that need to go into production quickly or require frequent design changes.

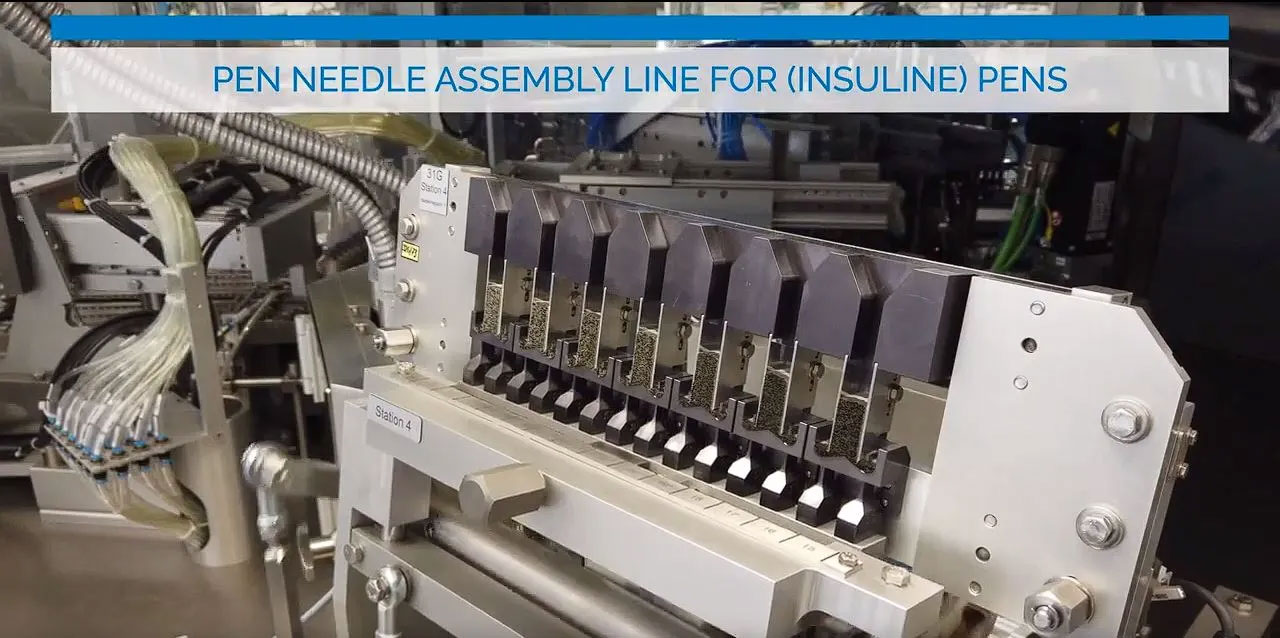

VIDEO

Pen Needle Assembly

UV adhesive, siliconization, to control and packaging of assembled pen needle.

Other Assembly Solutions

Autoinjector Platform

Pre-assembly to final assembly, semi-automated to fully automated systems tailored to specific requirements

Syringe Platform

Linear motion platforms that enable synchronous and asynchronous processing and configurable transfer systems for aseptic environments

ATS Discovery

Introducing and removing components, subassemblies, and finished product is a key aspect of an efficient operation

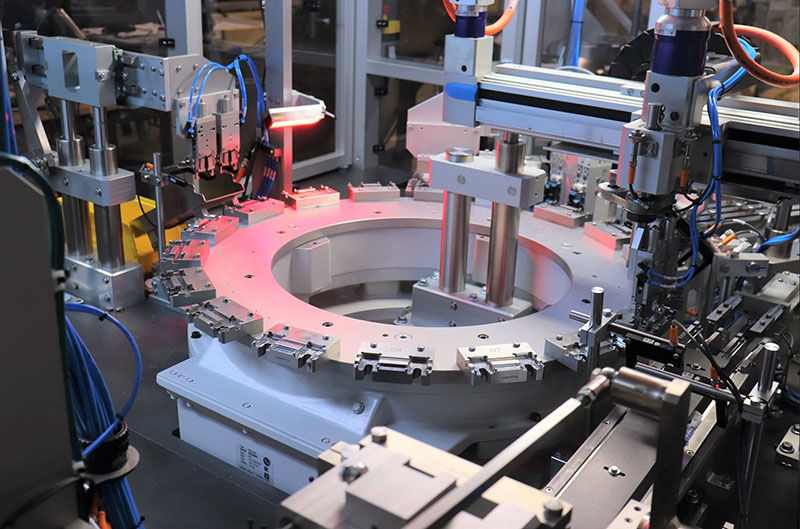

ATS OmniTrak

Product quality control and assurance through smart test, inspection, and digital monitoring

Symphoni

Product quality control and assurance through smart test, inspection, and digital monitoring

Looking For a Flexible Partner?

Jetwing was specially developed for assembling items that need to go into production quickly or require frequent design changes. We’re ready when you are.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube