Low volume device assembly and trayhandling

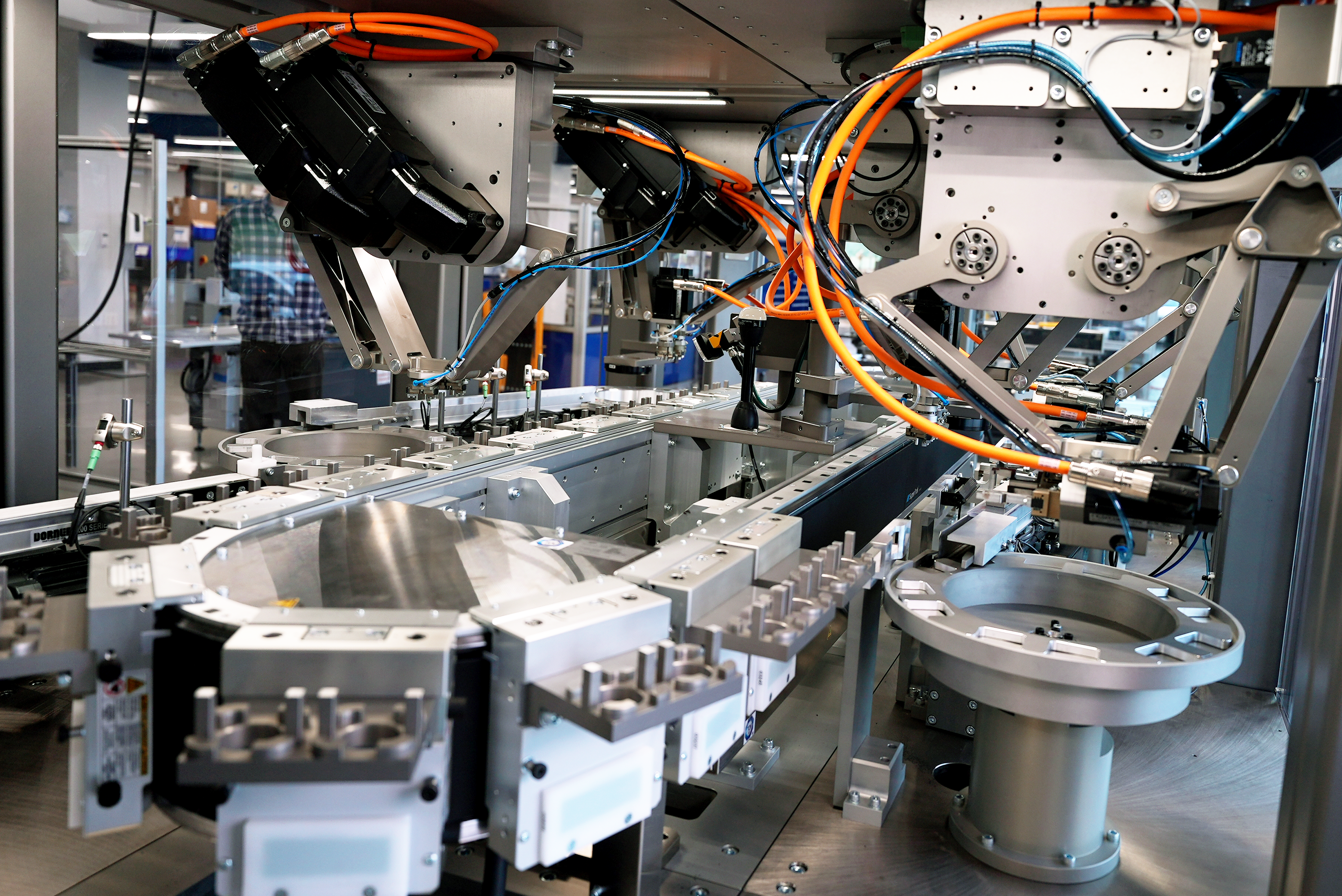

ATS SWIFTCELL™

Highly flexible modules providing the foundation for easy automated part handling and assembly of medical devices

ATS SwiftCell™

Standardized assembly modules are designed to meet the highest regulatory standards.

- Low volume: up to 20 ppm

- Pick and choose modules for transport, infeed/outfeed, and process stations

- Several vision options possible

OVERVIEW

SPECS

Features

- Highly standardized modules for picking and choosing

- Transport style: Robot, Dial, Belt and/or Conveyor

- Infeed/Outfeed solution: Flex feeding, vibratory feeding and/or manual loading

- Processes: Assembly, Handling, Gripping, Picking, Inserting and/or tray loading

- Fixed process griddimension for easy adaption

- Standard documentation and validation package

Applications

- Flexible low volume manufacturing

- Allows for future expansion with new processes or repurposing for a completely new product

- Customized processes possible according to customers´ needs

Recommended For

- Most types of Medical Devices: Safety syringes, Autoinjectors, Epipens, Inhalers, Contact lenses, etc.

Specs

- Output rate: Up to 20 ppm (customizable)

- Base Module: 1000 x 1000 mm

- Part weight: Up to 2 kg

- Several vision options possible

- Illuminate Manufacturing Intelligence

Other Assembly

Symphoni™ Technology

An innovative digital assembly platform that delivers high-performance, flexibility and quality. With a high degree of standardization and a modular design, it delivers speed, versatility, AND precision without compromise

OmniTrak™ Assembly Platform

An assembly platform that combines the precision of cam-controlled workstations and the flexibility of linear motor-driven workpiece carriers, offering high flexibility, lower maintenance, and optimized footprint

Discovery™ Assembly Platform

A dial-based, cam-driven platform perfect for high throughput, synchronized processes, with high production performance and easy maintenance

Autoinjector Assembly

Final assembly systems for any common three-piece autoinjector with scalable output rates between 2 ppm and 120 ppm

Syringe Assembly

End-to-end and turn-key services for glass or plastic assembly and handling, including our patented LED UV adhesive curing

Jetwing™ Assembly (Platform)

A compact, modular, and customizable linear platform developed specifically for assembling items that need to go into production quickly or that require frequent design changes

Accessible Automation for Low-volume Assembly and Trayhandling

The SwiftCell™ family of advanced standardized assembly modules is designed to meet the highest regulatory standards making us the go-to choice for leading medical devices manufacturers in the low volume sector.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube