- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Tray and Pallet Handling in Cleanrooms

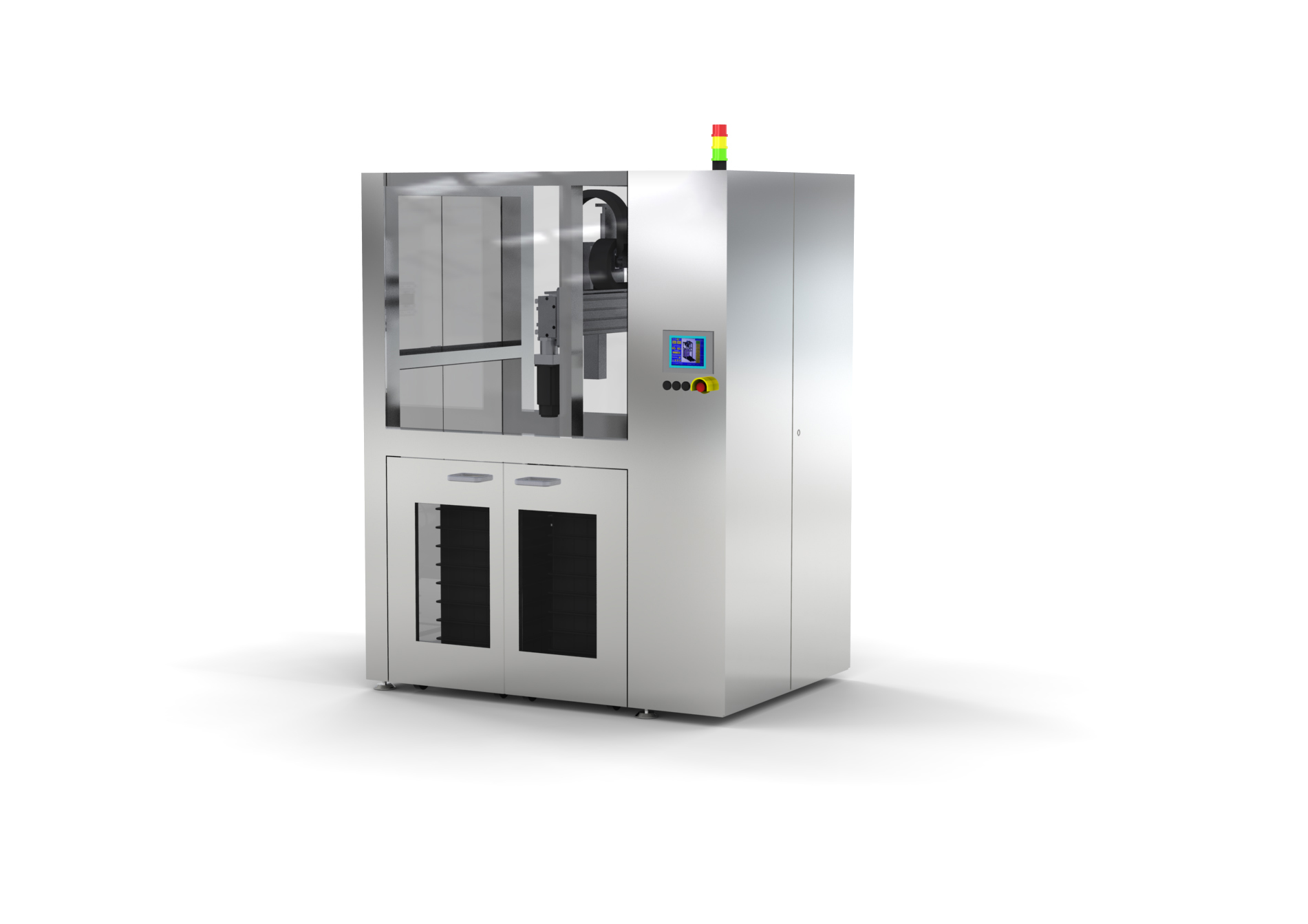

CLEARLINER TRAY AND PALLET HANDLING

Suitable for many medical device components, subassemblies and finished products including autoinjectors and glass cartridges

tray and Pallet Handling for Cleanrooms

Robust, dynamic and versatile, the Clearliner range was specially developed for efficient, dynamic automation in the pharmaceutical and medical sector.

- From straightforward tray handling tasks to complex, standalone feeding, inspection and assembly cells

- Space-saving footprint and ergonomic design

- Ideal for any tray or ISO/Euro pallet sizes from 400 to 1000 mm

The Clearliner Range

Clearliner 1000

This solution includes loading units that remove trays from pallets, and pick-and-place units that remove components from trays.

Clearliner 400M

Perfect for relatively lightweight trays, with optional positioning of part handling perpendicular to material flow. A popular choice for pharmaceutical products.

Clearliner 400V

Perfect for applications with relatively lightweight trays. Slimline design, small footprint and option of positioning part handling at rear of the machine make it an outstanding choice for feeding parts to assembly equipment.

Clearliner 400 S-T

Thanks to the many options and add-ons available, Clearliner 400/400S and 400T can be employed for a host of d rent applications. Con tions range

Key Benefits

Cleantrak conveyance and the Clearliner handling system work together in cleanroom automation systems.

Options for Trays

Options for Trays

Tray systems are available with a single axis, a speed version with 2 axes, and a version for cleanrooms up to class 1000 (ISO 6).

Options for Pallets

Options for Pallets

Pallet systems available with or without dedicated conveyors, and can be constructed for cleanrooms up to class 10K (ISO 7).

Adaptable

Adaptable

Depending on the quantity of parts and shape of the trays/pallets, we can integrate a conveyor belt or trolley for transfer to and from the machine. Stacks can then be removed or replenished while the Clearliner is in operation.

Made for Device Assembly

Made for Device Assembly

Suitable for many medical device components, subassemblies, and finished products including inhalers, autoinjectors, and glass cartridges.

Resources

BROCHURE

Cleantrak™ for Cleanroom Transfer

The ATS Cleantrak transfer system is the perfect solution for intelligently integrated, end-to-end automation. It is deployed in cleanrooms to link the Clearliner handling system to downstream automation systems.

VIDEO

Autoinjector Handling Line

Infeed line for labeling and packaging shows unloading of trays, position transfer, and transport.

Pallet and Trayhandling Under Cleanroom Conditions

Let’s discuss your conveyance technology needs for assembly under cleanroom conditions

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube