- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Pen body and pen needle assembly

PEN NEEDLE ASSEMBLY

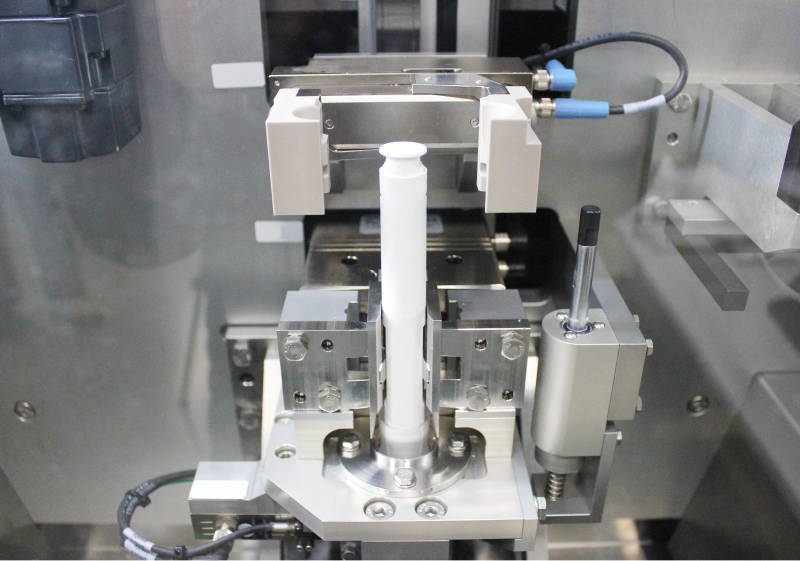

Several options for the manufacturing of injection pens. Our expertise includes the assembly of the pen body and the pen needle, both standard and safety needles, and final packaging.

Pen Needle Assembly

Equipment for various assembly processes for injection pens; fully automatic assembly lines for pen cannula; bonding cannula by induction welding or UV adhesive

- Cannula orientation: The correctly oriented needle is directly transferred to the cannula hub, guaranteeing maximum precision

- Cannula inspection: quality control of the cannula, from the needle bevel and tip, to the shape of the tube end

Features

Specs

Pen Body Machines

- Number of Components: 8-12

- Scalable Output Rate: Up to 200 ppm

- Options: Vision systems

- Platform: OmniTrak™

Pen Needle Machines

- Number of Components: For standard needle up to 3 + packaging; for safety needle up to 10 + packaging

- Needle Type: 29-33 G Scalable Output Rate: Standard needle up to 1200 ppm; safety needle up to 300 ppm

- Options: Vision systems, flow test, pull test, siliconization

- Platforms: OmniTrak™, SuperTrak™, or dial

Common to Both Pen Body and Pen Needle Machines

- Layout: Single or multi-module configurations available

- Controls: Rockwell or Siemens

- Data Management: Illuminate™ Manufacturing Intelligence – OEE Monitoring module

Specs

- Scalable output rate from 20 – 120 ppm

- Cleanroom Class: ISO 8

- Standard documentation package

- Reject rate < 1%

- Footprint: 8m x 5m (for 120 ppm)

- SCARA robot to achieve high speed and placement accuracy

- MORE >95%

- Loading options from manual to fully automated

- Controls: Rockwell or Siemens

Key Benefits

Ensuring a reliable supply of your quality product to the market is critical to your business.

Expertise

Expertise

Assembly systems geared to the special requirements of manufacturing subcutaneous and intra-muscular injection products

Material Handling

Material Handling

Glass cartridges require careful handling. Force applied when placing cartridges into the subassembly is defined and controlled, ensuring damage-free handling.

Inspection And Validation

Inspection And Validation

Each and every cartridge is inspected immediately before insertion into the pen sub assembly. The inspection unit is synchronized with the assembly machine.

Precision Manufacturing

Precision Manufacturing

Low- to high-volume assembly; seamlessly integrated processes. Processes from intake to packaging.

Other Injector Assembly

Pre-assembly and Final Assembly of Pen Needles

Our expertise includes assembly of the pen body and the pen needle, both standard and safety needles, and the final packaging. Let’s discuss your project.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube