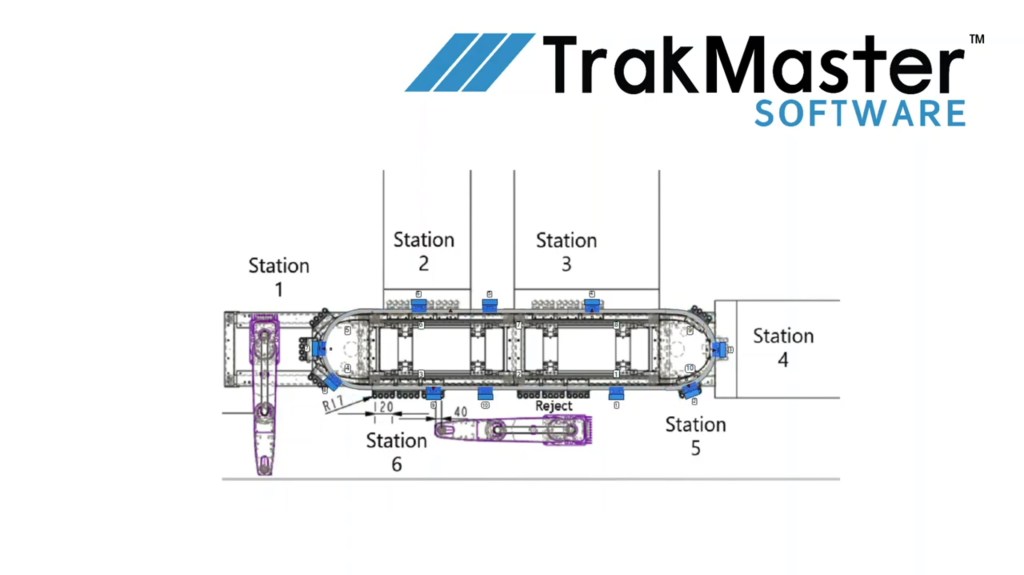

SuperTrak CONVEYANCE™ linear motion technology fundamentally changes the way you build and design automation. Individually controlled shuttles allow you to increase your throughput without an increased footprint, resulting in less complex and more adaptable automation systems. The TrakMaster™ software is the user interface that provides access to the track’s powerful integrated functionality.

- Smart conveyance platform with modular track

- Synchronous and asynchronous movement

- Maximum speed of 4m/s

- High degree of accuracy in placement and processing

- Individual shuttle control with payload of 10kg

- Adjustable shuttle and nest sizes

- Can be used as a base platform for assembly stations with output rates up to 400 ppm (depending on product)

- Asynchronous magnetic linear mover

- Track to track switching at full speed for sort and divert purposes

- Maximum speed of 3m/s

- Modular track with dual sided shuttle systems

- Light payload of 1.5-3kg

- Can be used as a base platform for assembly stations with output rates up to 120 ppm (depending on product)

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube