- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Advanced assembly of medical tube sets

TUBE SETS

Our flexible assembly platforms deliver high speed and quality for the assembly of complex coiled or straight tail segments. Minimal tooling ensuring the lowest total cost of ownership (TCO).

Take a Tour of the Coiling Machine

Alex Folz is Systems Design Engineer at ATS Life Sciences Chicago. He’s been the lead Systems Design Engineer on multiple tube set assembly programs during his tenure, including multiple innovation projects relating to tube sets.

In this video, Alex shows the flexible machine working and explains how it handles product variance, the shift from cam-based technology, the benefits of adding synchronous servo pneumatic technology at the station level, mastering consistent tube tension, and meeting the need for this medical consumable.

Advanced Technology in Tube Set Manufacturing: Future Proofing Tube Set Assembly Through Flexible Automation

When assembling medical tube sets, two of the most important factors to the manufacturer include output volume and product quality. To this end, ATS has developed a multitude of innovations to address each of these needs.

DOWNLOAD NOW

Download our whitepaper to explore the innovations that mean automating this consumable can still deliver ROI.

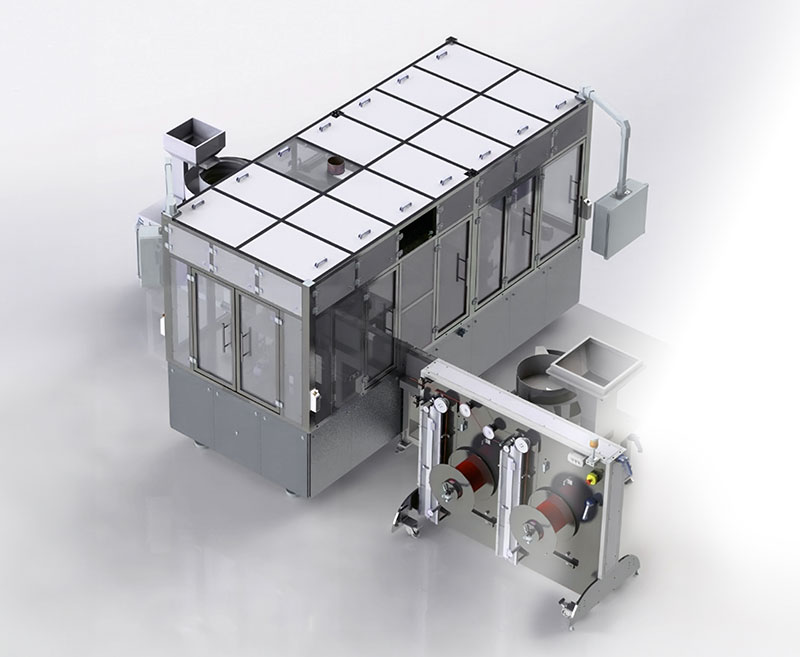

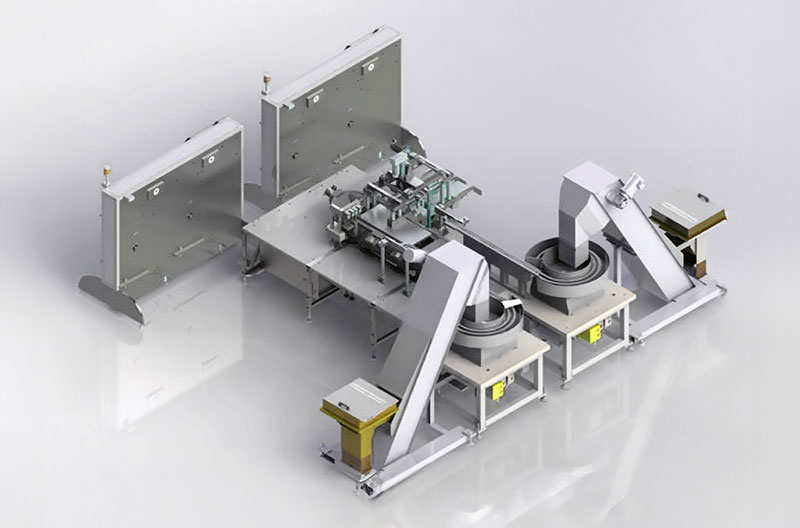

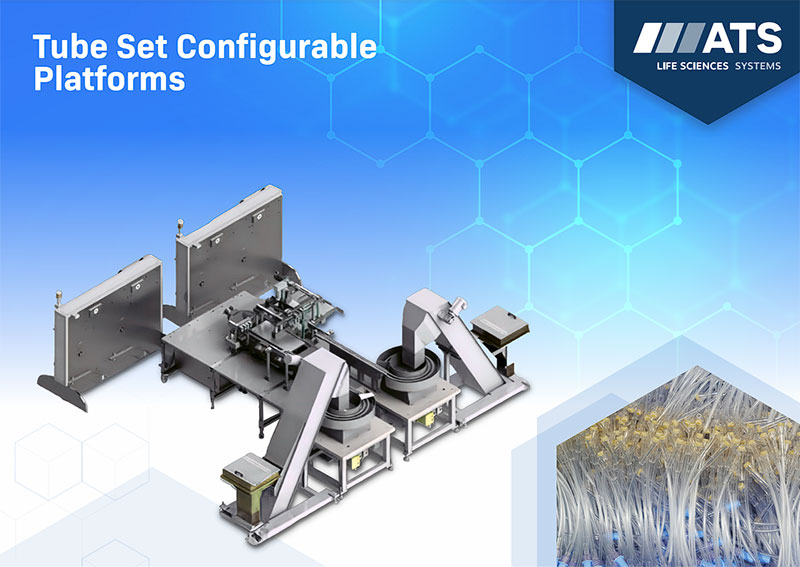

TUBE SET CONFIGURABLE PLATFORMS

MDTubeSet30

An entry-level machine for low-volume throughput; a synchronous over/under indexing conveyor with cam-driven stations. Up to 30 ppm without additional tooling.

MDTubeSet60

A synchronous, servo-driven machine on a SuperTrak CONVEYANCETM platform. Dual sided de-reelers allow tube changeout without stoppage. Vibratory hoppers meter parts for hours of walkaway time.

MDTailSegment180

A synchronous, servo driven machine stationed on a SuperTrak CONVEYANCETM platform. Ultra sonic cutting for reduced particulate. This is the ultimate solution for high-runner tail segment SKUs.

Medical Tube Sets

Transforming efficiency in Tube Set manufacturing! Our advanced Tube Set assembly platforms deliver high speed, quality, and reliability, ensuring the lowest total cost of ownership (TCO).

- Product – Complex coiled or straight tail

- Platform – SuperTrak CONVEYANCETM

- Cutting – Ultrasonic blade

- ISO Level – ISO 8 standard or custom

ATS is the Right Assembler for your Medical Tube Sets

Efficiency and reliability are redefined with our advanced Medical Tube Set Assembly platforms. Engineered to outperform, our machines provide robustness and dependability, elevating your operations to greater speed and efficiency.

Increased speed – Servo-based stations have blended motions that minimize wasted time during each cycle, leaving more time for the key assembly processes.

- Proven linear motion technology.

- Ship more sets for less cost with reduced operator fatigue and turnover.

- Surpass the competition with a solution that’s not just better, but the best in its class.

Minimize Costs for Disposable Medical Tube Sets

In the world of medical tube set manufacturing (IV, dialysis, blood collection, infusion, apheresis), end users are not willing to pay top dollar for what is considered a ‘disposable’. Automation can make it attainable.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube