Maximum output for a minimal investment in the smallest footprint

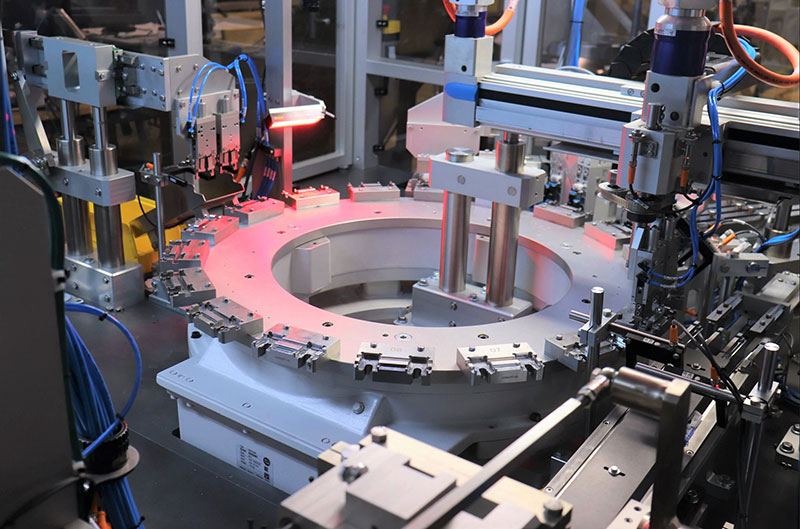

SYMPHONI™

An innovative high-speed manufacturing solution that combines standardization and speed with gentle part handling. Assembly rates from 40 – 1100 PPM with a much smaller footprint than conventional assembly equipment.

Symphoni™

Digital assembly platform that is pre-engineered, highly standardized and modular. A general-purpose asset that surpasses conventional systems in flexibility, speed, and precision.

- Patented RSM Technology® enables tight coordination of integrated, multi-axis robotic arms

- Compact, configurable, and modular construction reduces footprint

- End-to-end digital awareness, with status and position of each system device, mapped out in 1-millisecond intervals, verified 200 times per second by self-diagnostics

Features

- High flexibility of pallets & robots

- Pre-engineered, plug-and-play design

- 85% standardized and modular; 90% less tooling than conventional equipment

- Ultra-precise motion control with a delicate touch

Applications

- R&D

- Clinical and low-volume production

- High-volume assembly; variable speed capable of 10 – ~1000 ppm

- High-volume/low-mix & low-volume/high-mix products

Recommended For

- Autoinjectors, pens (4 – 10 components)

Output: up to 400 ppm - Eye dropper bottles and lids (2 – 3 components)

- Tube sets >10 components

Output: up to 320 ppm - Inhalers

Output: up to 320 ppm

Other Assembly Solutions

Autoinjector Platform

Pre-assembly to final assembly, semi-automated to fully automated systems tailored to specific requirements

Syringe Platform

Linear motion platforms that enable synchronous and asynchronous processing and configurable transfer systems for aseptic environments

ATS Jetwing

Introducing and removing components, subassemblies, and finished product is a key aspect of an efficient operation

ATS OmniTrak

Product quality control and assurance through smart test, inspection, and digital monitoring

ATS Discovery

Product quality control and assurance through smart test, inspection, and digital monitoring

Symphoni™ Gives You the Edge

Technology that transforms the way you invest in automated assembly. Enhanced servo-based motions and e-cams mean a single system can run multiple product lines 24/7with 90% less retooling.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube