High-level processes for your medical automation

MANUFACTURING PROCESSES

We can optimize your project with a variety of skills and processes to innovate and improve your medical production. From off-the-shelf and easily integrated to highly customized and leading edge, we’re your partner

Manufacturing Capabilities

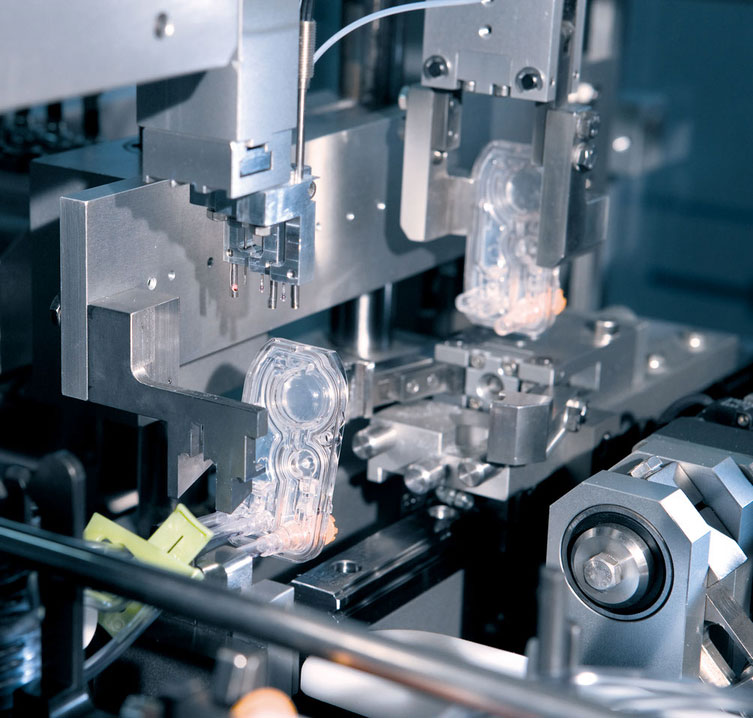

Assembly

Platforms and technology for simple or complex assembly with scalable output rates, synchronized or asynchronous processes, with precision, efficiency, and easy maintenance.

Platforms and technology for simple or complex assembly with scalable output rates, synchronized or asynchronous processes, with precision, efficiency, and easy maintenance.

Learn More

Plastic Joining

Perfect weld seams and spots for products that function correctly, reliably and without leakage. Ultrasonic Welding, Laser Welding, Adhesive Dispense to ensure seamless integration for this challenging process.

Perfect weld seams and spots for products that function correctly, reliably and without leakage. Ultrasonic Welding, Laser Welding, Adhesive Dispense to ensure seamless integration for this challenging process.

Contact Us

Curing

Thermal processes, or LED and ultraviolet (UV) light-curing of various adhesives with cure time optimization for lowest impact to system rate; ideal for consumable medical devices like tube sets, pen needles, autoinjectors, and glass syringes.

Thermal processes, or LED and ultraviolet (UV) light-curing of various adhesives with cure time optimization for lowest impact to system rate; ideal for consumable medical devices like tube sets, pen needles, autoinjectors, and glass syringes.

Learn More

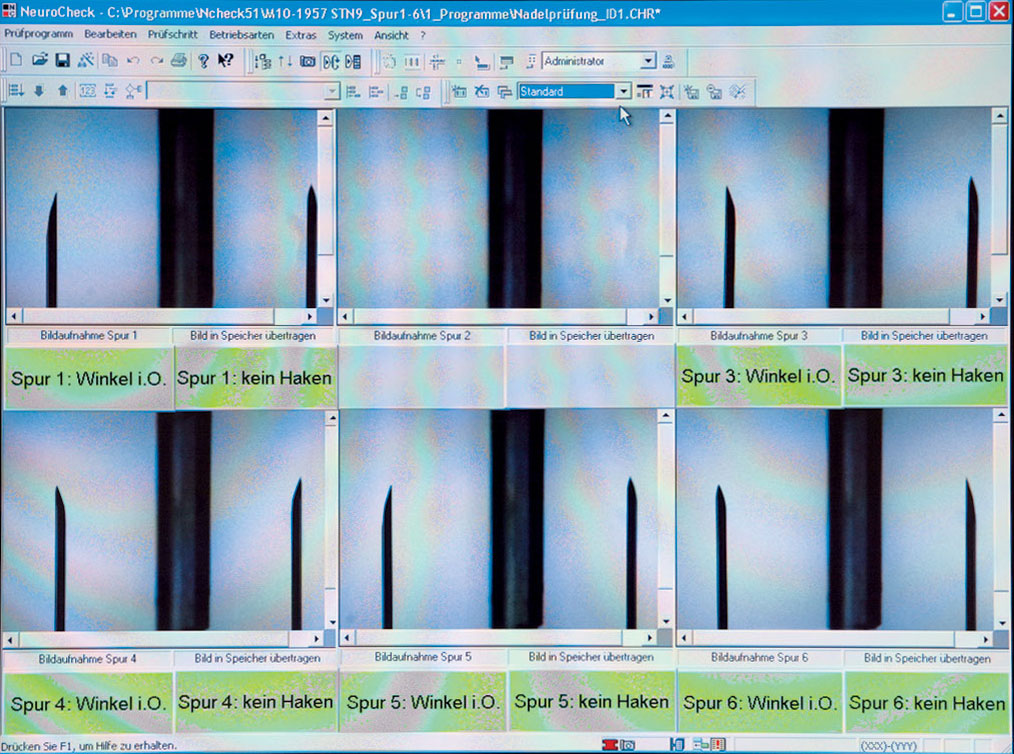

Cannula Tip Forming

Injection products, such as safety syringes and IV catheters, must be precision manufactured. Tip forming requires precisely shaping the tube around the cannula. The correctly oriented needle is directly transferred to the cannula hub for maximum precision.

Injection products, such as safety syringes and IV catheters, must be precision manufactured. Tip forming requires precisely shaping the tube around the cannula. The correctly oriented needle is directly transferred to the cannula hub for maximum precision.

Contact Us

Glass Forming

Custom and OEM capabilities. Production of full apparatus from tubes and rods.

Integrated processes to optimize your automation

Contact us to set up a meeting about your project or process. Together we’ll find the right solution that generates the results you need.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube