- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

The right automation solution for your autoinjector

AUTOINJECTOR FINAL ASSEMBLY

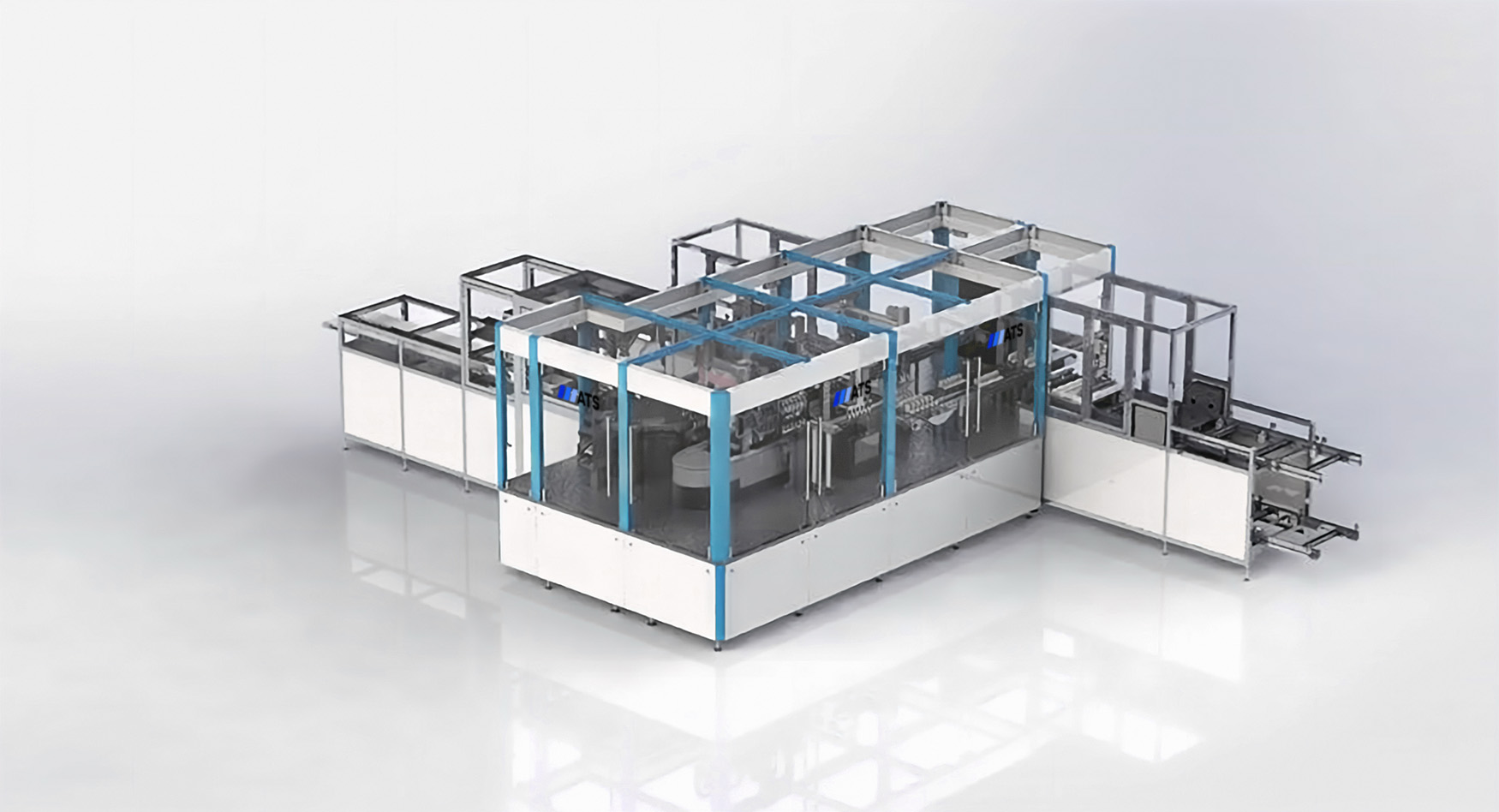

Our autoinjector assembly systems for any autoinjector provide scalable output rates from 2 ppm – 320 ppm. Standard or Custom engineering available

Standard Autoinjector Platform

Our expertise ranges from the pre-assembly of sub-components to the final assembly of autoinjectors.

- Output rates: 2 – 320+ ppm

- Suitable for the assembly of any common three-piece autoinjector

- Predesigned for shorter delivery times, optimized foot print and lowered power/air usage.

OVERVIEW

SPECS

Features

- Quick retooling of stations to accommodate new products or variants

- Quick retools, combinations of stations via interfaces, introduction of new stations/modules or product changes

- Can be combined with manual workstations

Applications

- Ideal for products with a small number of parts, or ones still under development

- Reusable: Individual functions can be replaced

- Ideal for the product development phase and assembling large quantities of products with short lifecycles

Recommended for

- Specially developed for assembling items that need to go into production quickly or require frequent design change

- Pumps, tube sets, blood collection, syringes, inhalers, other medical devices

- Multiple-track assembly possible

Specs

- Scalable output rate from 20 – 320+ ppm

- Cleanroom Class: ISO 8

- Standard documentation package

- Platform: SuperTrak™ with stations

- Reject rate < 1%

- Footprint: 8m x 5m (for 120 ppm)

- SCARA robot to achieve high speed and placement accuracy

- OEE >95%

- Loading options from manual to fully automated

- Controls: Rockwell or Siemens

Key Benefits

Standard as well as highly-customized solutions while always staying flexible and innovative.

Exceptionally Versatile

Exceptionally Versatile

Perfect for manufacturing either low or high volumes of items, and for both semi- and fully-automated assembly. Accommodates both round and cut flange syringes.

Lower Design Costs

Lower Design Costs

Pre-engineering means lower design costs and faster delivery for standardized platforms. Capable of handling external drive units. Optimized compact floor space designs.

Sustainable

Sustainable

Connected factory floor management system for superior manufacturing OEE, productivity, and product quality. Low maintenance and minimum power/air usage.

Customizable

Customizable

A wide variety of customization options such as manual workstations, feeder units or tray handling. Process technologies and testing systems can be integrated, such as vision systems and tests for leakage and back pressure.

Low Volume Autoinjector Assembly

Semi-automated, servo-driven cell for pre-testing, verifying and validating the assembly of syringes.

- Output rate: 2 ppm

- Suitable for clinical trials and product development phase

- Ensure proper device assembly with force-displacement feedback

OVERVIEW

SPECS

Features

- Automation for validating combination device assembly

- Transferable and scalable for high volume

- Force-distance control to verify good part assembly

- Data management for auditing and traceability

- Small footprint for manufacturing flexibility

Applications

- Ideal for clinical trials, orphan drugs, and personalized medicine

- Reusable: Individual functions can be replaced

- Ideal for the product development phase and assembling large quantities of products with short lifecycles

Recommended for

- Autoinjectors (Device-Body / Device-Drive Unit / Pre-filled syringe)

- Pen injector (Device-Cartridge holder / Device-Dosing Mechanism / Cartridge)

Specs

- Output rate: 2 ppm

- Footprint: 1100 x 720 mm

- Weight: 320 kg

- Height: 1030 mm

- Communication: Ethernet Protocols

- HMI: 7″ Touchscreen

- Power: 230 V. 20 A. 50 Hz

- Availability: on shelf

- Documentation: Standard package

Key Benefits

Standard as well as highly-customized solutions while always staying flexible and innovative.

Exceptionally Versatile

Exceptionally Versatile

Perfect for manufacturing low volumes with adjustable station properties.

On-shelf Solution – Low cost

On-shelf Solution – Low cost

Available for shipment within days for your clinical trials.

Resources

VIDEO

Autoinjector Handling Line

Infeed for labeling and packaging, handling of trays, position transfer, transport.

BROCHURE

Final Assembly for 3-Piece Autoinjector for Mid/High-Volume

End-to-end automation solution for YpsoMate®-style autoinjector assembly. Configured for shorter delivery times.

BROCHURE

Final 3-Piece Autoinjector Assembly Systems

Our final assembly solutions are suitable for scalable output from 2 to 320+ ppm. Shorter delivery times, optimized footprint, and lowered power/air usage.

Final Assembly of Autoinjectors

Our standard autoinjector solution is pre-engineered for lower design costs and faster delivery. As the demand for tools for the self-administration of drugs increases, you need manufacturing processes that are safe, reliable, compliant, and customizable.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube