- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

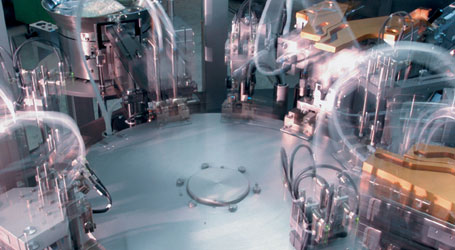

Rotary Indexing Cam-based System

ATS Discovery™

A configurable transfer system for intelligently integrated, end-to-end automation. Links the Clearliner™ handling system to downstream automation.

ATS DISCOVERY™

Central cam-based control for precision and reliability; machine configuration up to 24 tracks and/or 150 cycles per minute

- Flexible feeder systems suitable for any component

- Custom-designed systems using standardized technology

- Roundtable assembly system

OVERVIEW

SPECS

Features

- Central cam-based control for precision and reliability

- Flexible feeder systems suitable for any component

- Dial movement is generated by an indexer coupled to the main drive shaft producing a synchronized machine

Applications

- For assembling market-ready products in large quantities

- Multiple rotary indexing machines can be combined for higher output

- Achieves high production performance due to high repeatability of cam driven stations

Recommended For

- Class 10,000 (ISO 7) cleanrooms, up to class 100 (ISO 5) possible

- Drug delivery, inhalers, pumps, tube accessories, syringes, IV catheters, etc.

Specs

- Machine configuration up to 24 tracks and/or 150 cycles per minute

- Options: special versions such as two interlinked rotary indexing machines

- Stations: 12, 16 or 20 available as standard

- Made from easy-to-clean materials such as anodized aluminum and stainless steel

- PLCs: Siemens S7 or Allen Bradley CLX

- Stations can be equipped with hoods for stringent cleaning

Key Benefits

Compact

Compact

Space-saving design ideal for the assembly of large quantities of complex, market-ready products. 12, 16 or 20 stations are available as standard.

The Right Drive

The Right Drive

Rotary indexing tables are based on a central cam drive, enabling rapid, precise and reliable assembly. The rotary table is indexed by a gear synchronized with the main drive shaft.

Easy to Clean and Maintain

Easy to Clean and Maintain

Layout guarantees easy access from all sides. Made from easy-to-clean materials such as anodized aluminum and stainless steel. For more stringent requirements, stations can be equipped with hoods.

Customizable

Customizable

Discovery is available in custom formats with between 8 and 32 stations, or as a solution comprising two inter-linked rotary tables, tailor-made for your product.

Resources

BROCHURE

Dial Assembly Solution

Discovery delivers outstanding performance and reliability for non-stop operation with a variety of innovative features

VIDEO

Plastic Syringe Assembly

Rotary indexing tables are based on a central cam drive, enabling rapid, precise and reliable assembly.

Other Assembly Solutions

Autoinjector Platform

Pre-assembly to final assembly, semi-automated to fully automated systems tailored to specific requirements

Syringe Platform

Linear motion platforms that enable synchronous and asynchronous processing and configurable transfer systems for aseptic environments

ATS Jetwing

Introducing and removing components, subassemblies, and finished product is a key aspect of an efficient operation

ATS OmniTrak

Product quality control and assurance through smart test, inspection, and digital monitoring

Symphoni

Product quality control and assurance through smart test, inspection, and digital monitoring

Do You Need Guaranteed High Performance?

The Discovery rotary indexing machine is a proven solution, tried and tested in harsh production environments. It delivers outstanding performance and reliability for non-stop operation.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube