In pharmacies, automated storage and retrieval systems (ASRS) are gaining popularity as a result of the advantages they offer over conventional manual storage techniques. As the name implies, these systems are created to automate the storage and retrieval of objects like pharmaceuticals and other medical products.

An ASRS enhances overall inventory management accuracy and turnover and offers better control over the security and accessibility of the goods. It can keep track of prescription medicines and their expiration dates, alerting pharmacy workers to pending requirements to reorder. With the ability to operate under FIFO (First-In, First-Out) logic, the risk of unused medication expiring is reduced. An automated structure lowers the possibility of human error while also making it simple for pharmacy employees to find and collect items as needed; furthermore, automation not only saves time, but also lowers the possibility of human error-related mistakes and rework. A range of controls can reduce rework, variability and contamination, resulting in improvements in quality and reproducibility.

“Automation not only saves time, but also lowers the possibility of human error-related mistakes and rework.”

Using an ASRS in a pharmacy enables improved item organization and classification. The system can be set up to store things according to their type, such as OTC (over-the-counter) drugs, prescription drugs, controlled substances, or medical supplies.

A seamless information transfer across systems is made possible by an ASRS’s ability to interact with other systems, such as Electronic Health Record Systems (EHRs). This integration facilitates easy medication tracking and ensures that the right drug is given to the right patient at the right time. Increased traceability and patient-specific packaging can lead to improved patient compliance and outcomes.

ASRSs are made to be intuitive and simple to use. The system can be modified to match the unique requirements of the pharmacy or pharmacists, and it can be operated via a computer or other electronic device. This implementation helps shorten training time and makes it simple for pharmacy employees to access and retrieve products.

Speaking in terms of sustainability, this approach to pharmacy storage is both economical and environmentally friendly. ASRS systems are made to use less energy and produce a smaller carbon footprint. They do away with the requirement for additional personnel or tools to manage storage and retrieval operations, allowing staff to be redeployed to higher-value activities including patient interaction. By automating tedious manual processes and lowering human error, it can also lower total operational expenses over time.

In completely practical terms, the potential to conserve space is one of the main benefits of employing an ASRS in a pharmacy. An ASRS can store many products in a relatively small footprint as opposed to traditional storage systems, which frequently require a lot of physically accessible room. Space usage can be maximized by the system’s use of vertical storage and retrieval. Enhanced effectiveness is another advantage of employing an ASRS in a pharmacy; automating many of the operations involved in storing and retrieving goods (receiving, sorting, scanning, data entry, shelving) can save time and labour when compared to manual systems.

“With advancements in automation and design, it is not only large facilities and chains that can consider this technology.”

With advancements in automation and design, it is not only large facilities and chains that can consider this technology. Manufacturing principles provide the ideal application for labs and pharmacies meaning automation solutions are no longer out of reach for even small facilities. There is no need to limit your operation to traditional manual solutions when up-to-date systems are accessible and scalable for higher throughput or slower-moving applications.

Pharmacies must have the required equipment and technology to protect the security and welfare of their employees and customers in the quickly changing healthcare environment of today. By introducing automated systems, workplace safety is improved, and patient-specific packaging can lead to better patient compliance and outcomes.

Compared to conventional manual storage methods, automated storage and retrieval systems offer a variety of advantages that can aid pharmacies in spatial optimization, efficiency, accuracy, and security. They can also lower instances of human error, enhance inventory management and security, and deliver better overall patient care. As a result, an ASRS could be a wise investment for pharmacies.

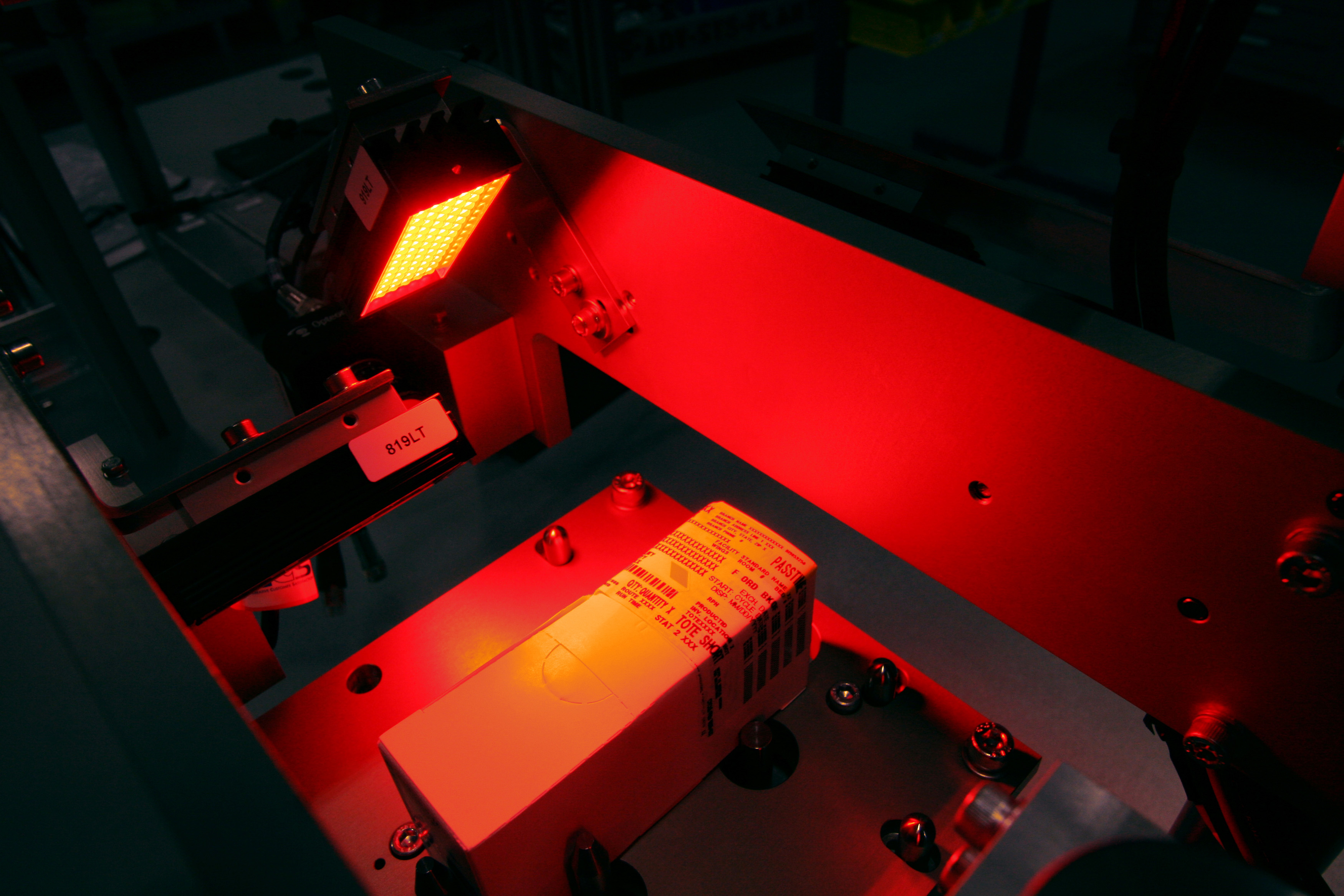

In larger applications, the addition of Autonomous Mobile Robots (AMR) or intelligent vehicles help streamline internal logistics by performing routine tasks and operating independently to move materials. Machine vision technology can identify, grab, and move objects from one location to another.

In summary, automated storage and retrieval systems are a crucial and increasingly accessible piece of technology that can assist pharmacies in streamlining their inventory management, increasing their productivity, and delivering patients better treatment. An ASRS can save time, reduce errors, and enhance inventory control since it can automate many of the operations related to storing and retrieving products. Additionally, they are made to be simple to operate and user-friendly, which cuts down on training time. The long-term benefits of ASRS investments for pharmacies include improved patient care and cost effectiveness.

Visit our website to explore the breadth of our life sciences applications and capabilities: https://www.atslifesciences.com/. To learn more about automated storage and retrieval systems or the potential for automation in your current or pending process, please contact us.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube