- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

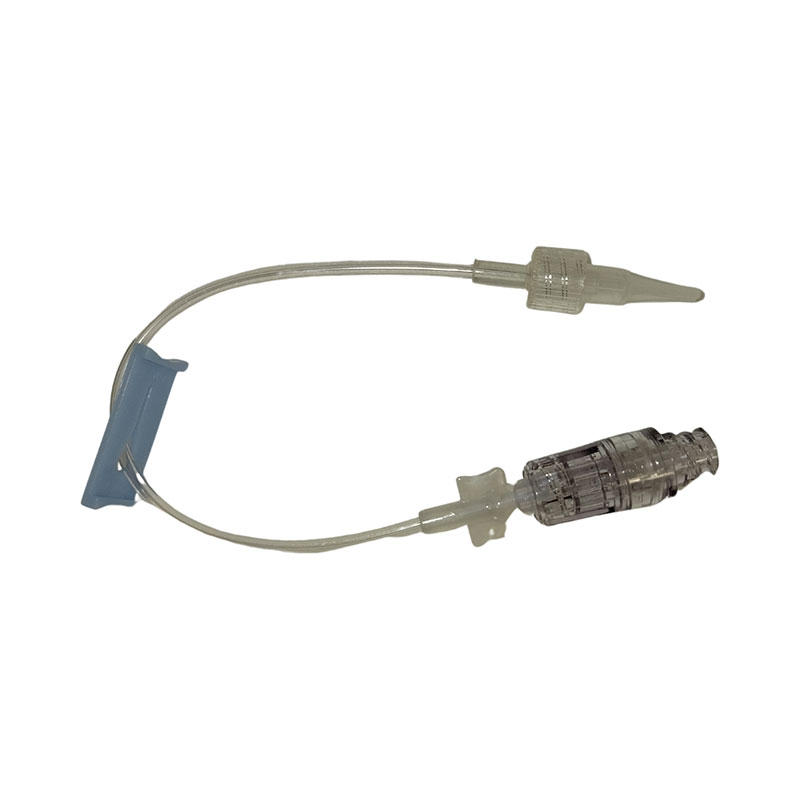

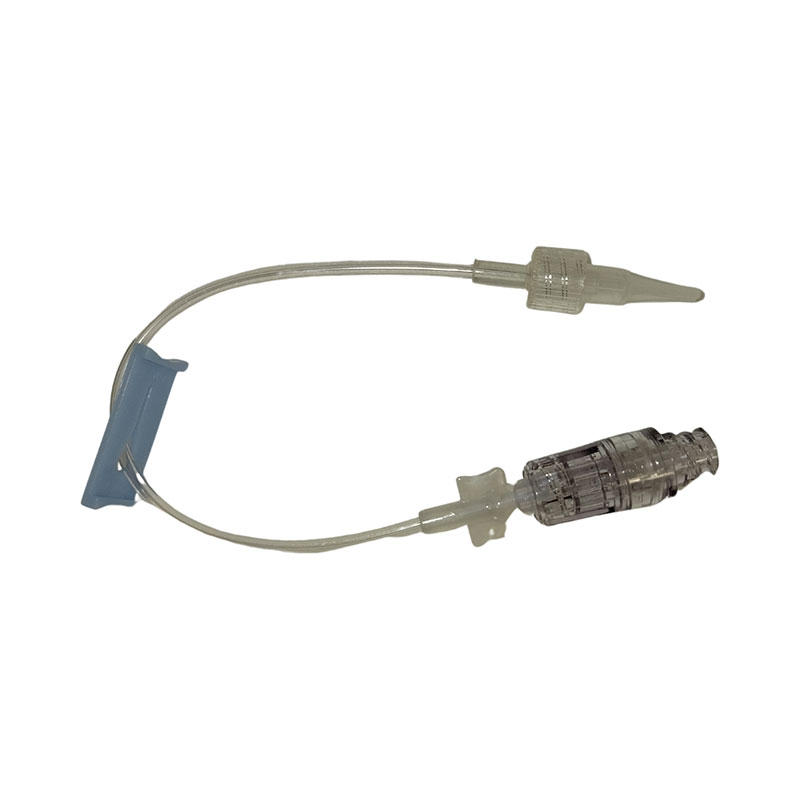

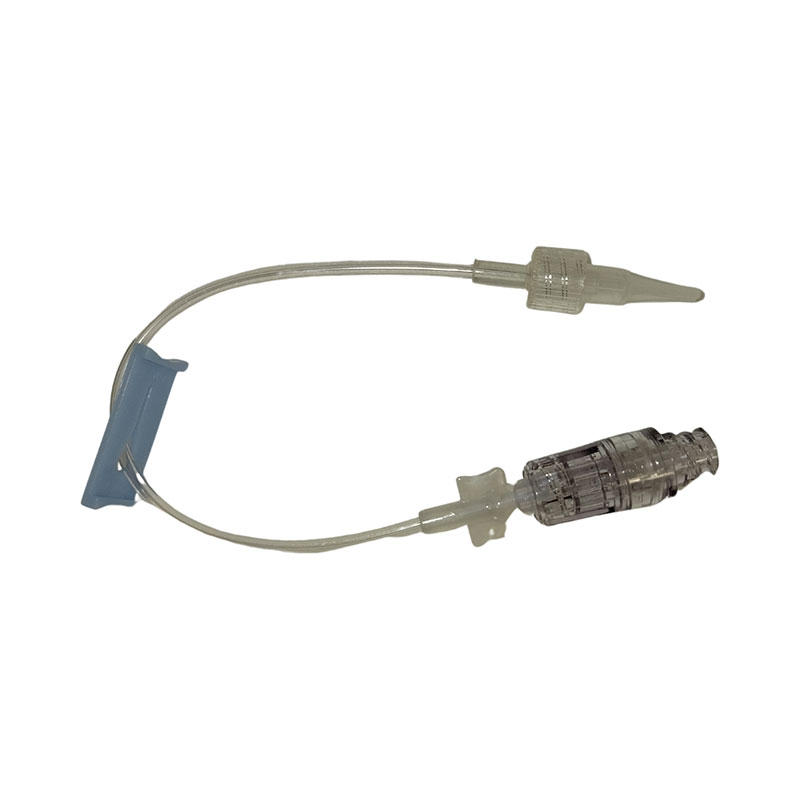

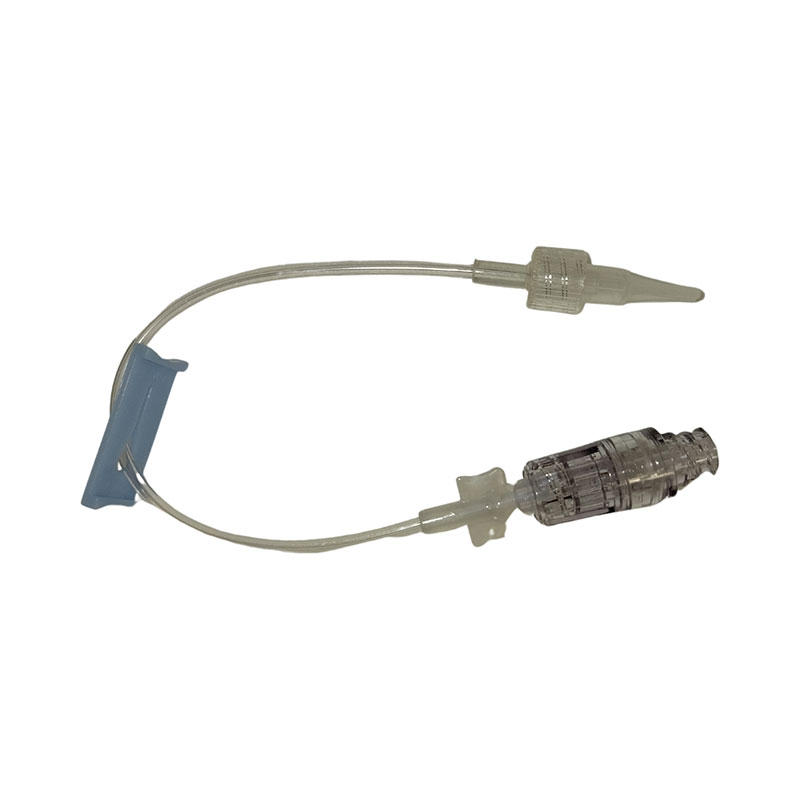

Medical Tube Sets

Output Level: Up to 180 ppm

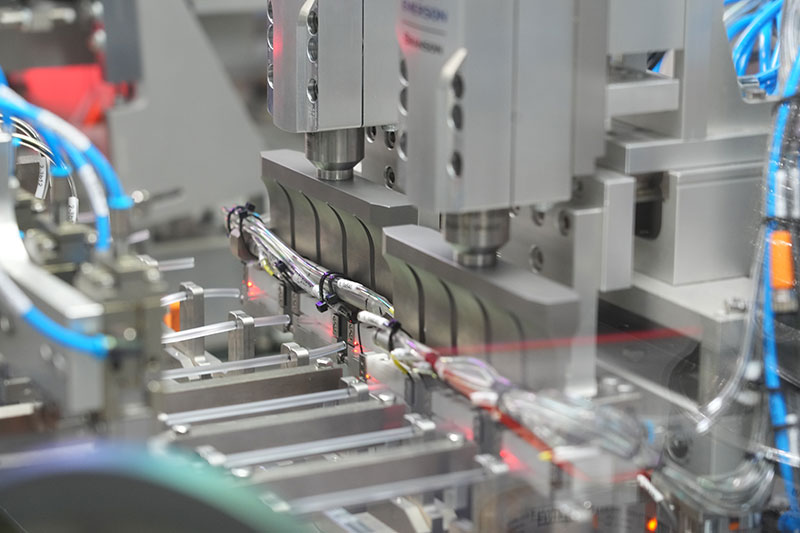

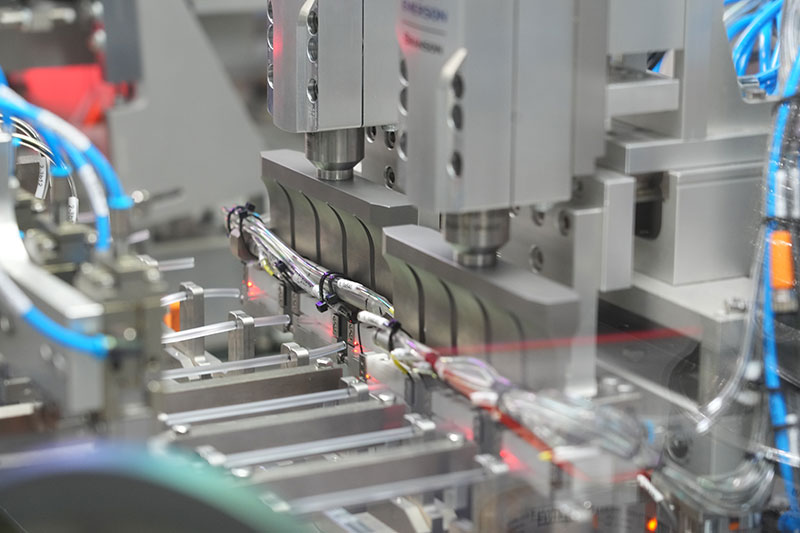

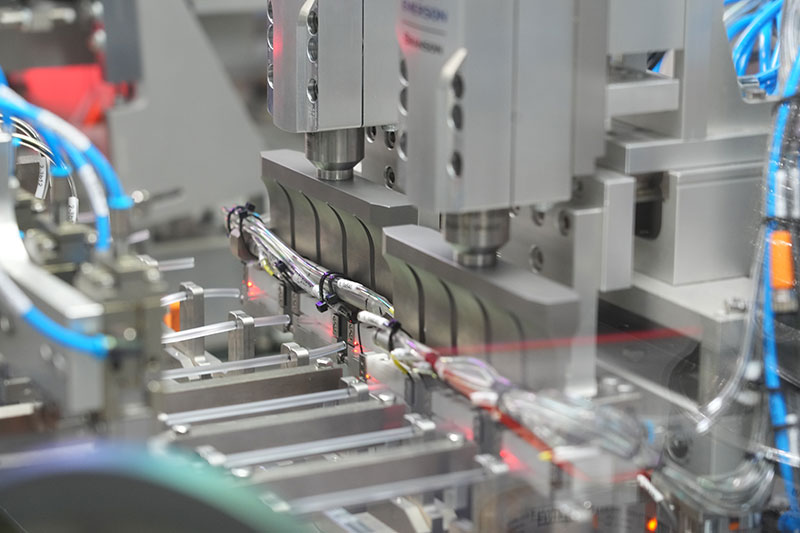

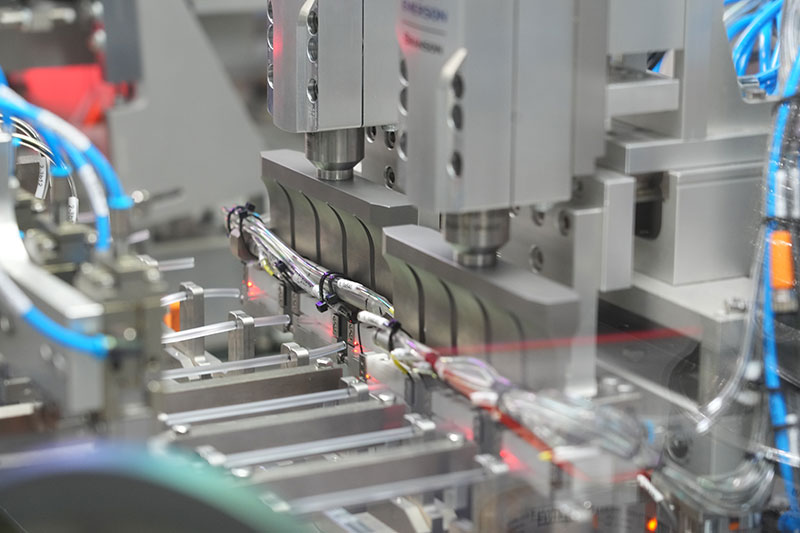

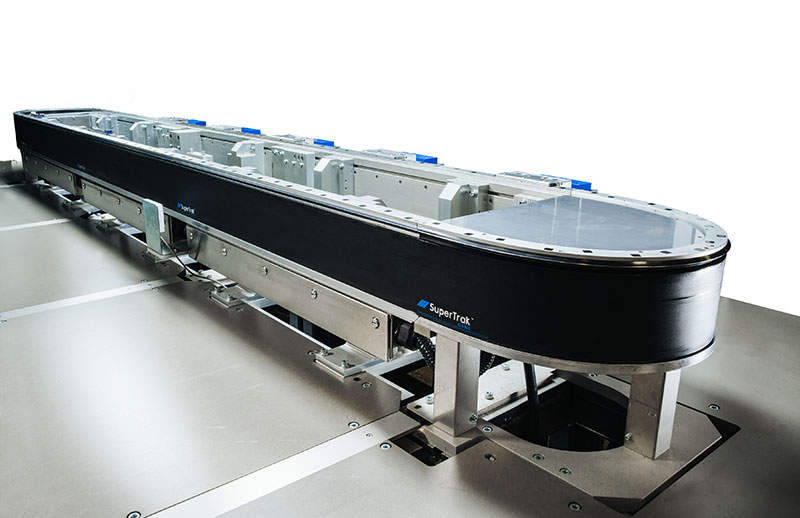

The MDTailSegment180 is a synchronous, servo driven machine stationed on a SuperTrak CONVEYANCETM smart conveyance platform. This is the ultimate solution for high-runner tail segment SKUs.

- Product – Straight tail segments

- Platform – SuperTRAK CONVEYANCETM

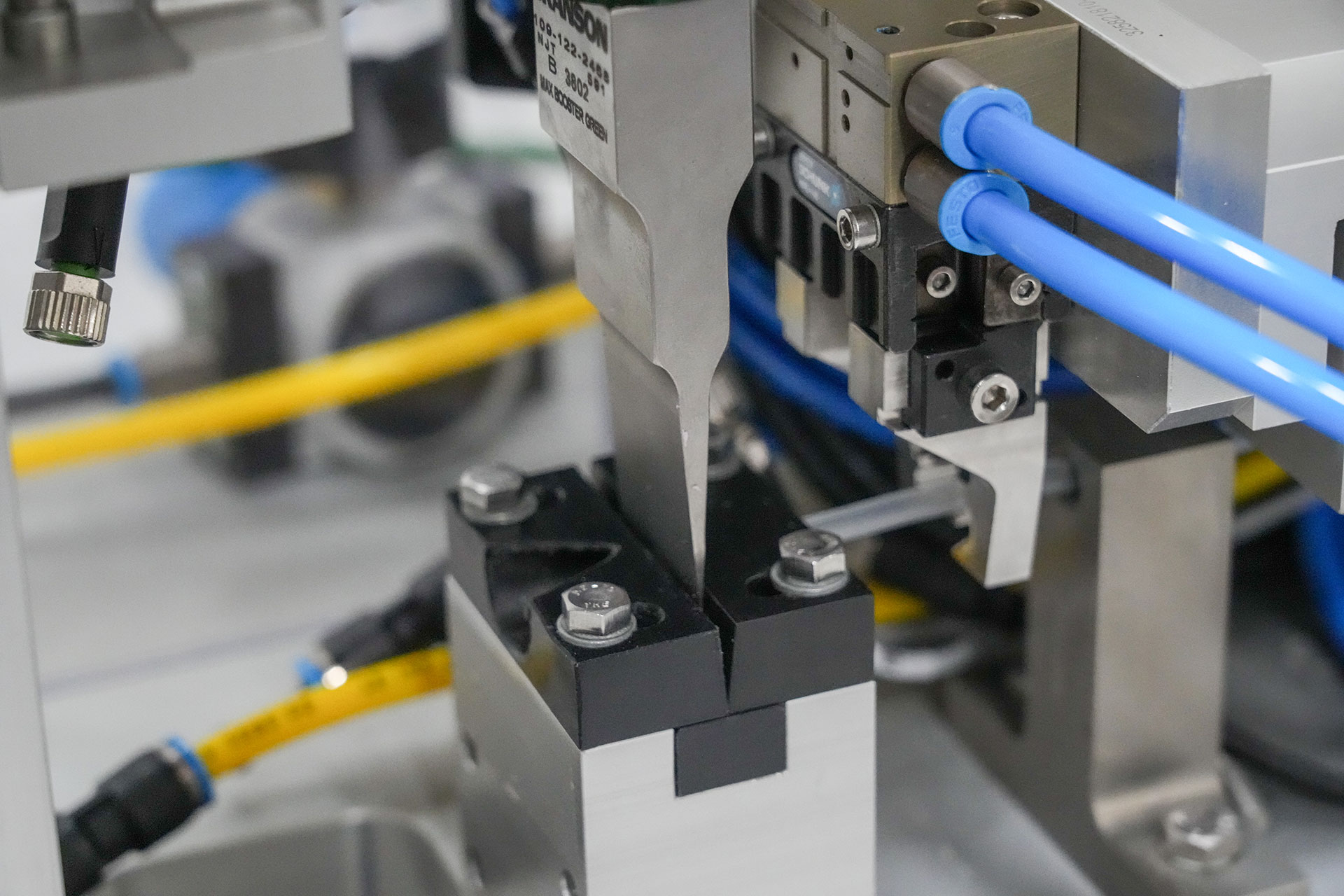

- Cutting – Ultrasonic blade

- ISO Level – ISO 8 standard, or custom

Medical Tube Sets

Output Level: Up to 180 ppm

✕

STRAIGHT SEGMENTS

Features

- Output up to 180 ppm

- System size is minimized to have space for value-add processes only, minimizing WIP parts

- Faster rate: Yields a smaller footprint and fewer material loading points (less operator time)

Recommended for

- Straight tail segments

- Multi-track systems (60 parts per minute for each track, to a maximum of 3)

- High-runner tail segment SKUs

Learn More About Smart Conveyance

SuperTrak CONVEYANCETM is a fully programmable linear motion technology with independent and parallel workstations. Smart technology with asynchronous sub 10 micron resolution and precision, single PLC control system, fully scalable and configurable to meet complex challenges and varying outputs.

Learn More About IlluminateTM Manufacturing Intelligence

Utilize onboard reporting and diagnostic tools for production performance monitoring. Simplify the collection and analysis of data from automated manufacturing systems. With Illuminate software installed, operations and maintenance personnel can quickly understand situations and prioritize actions.

Resources

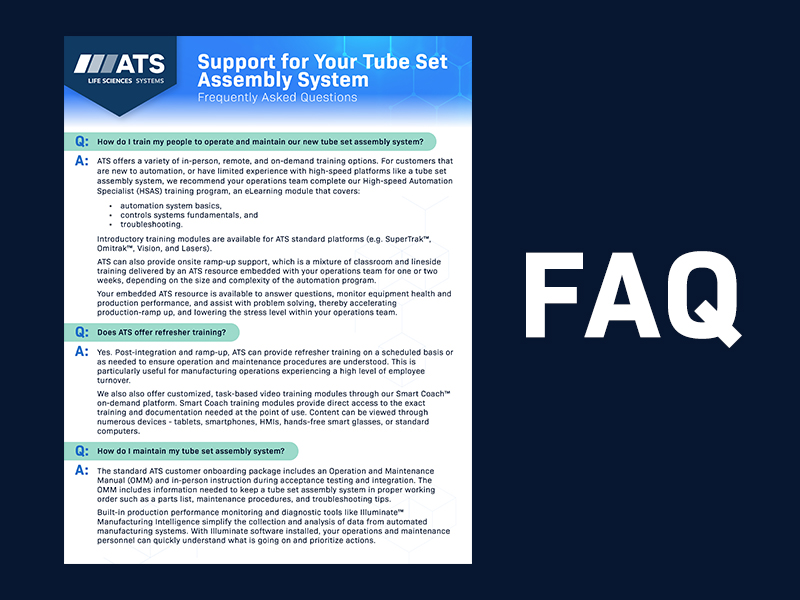

FAQs

Support for Your Tube Set Assembly System

Maximizing your ROI with ramp-up support, onsite or remote training, and troubleshooting.

Case Study

Building New Versus a Proven Performer

Our customer was using a system that met their needs until a new order required additional output. The demand exceeded the 120 ppm capacity, LSS was challenged to develop a 180 ppm solution at less than a 50% cost increase.

Blog

Long-Term Value and Support

No two systems are alike and neither is the need for post-integration support. Identify and manage risks and promote proactive maintenance to lower TCO.

Podcast

E1: The Evolution of Medical Tube Set Manufacturing

Howie Spieden reflects on changes to cams, linear motion technology, vision inspection systems, and manufacturing intelligence.

Reduced start-up time, particulate, and power usage make automating this medical consumable attainable

ATS is a proven tube set assembler, solving your manufacturing challenges to get you to market fast. Tailor modules to meet demand and available footprint.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube