- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

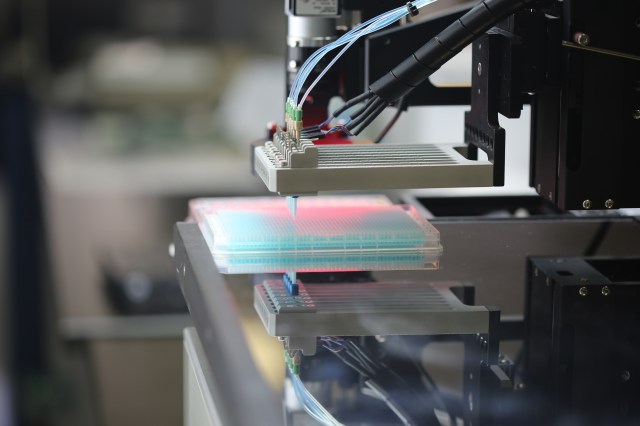

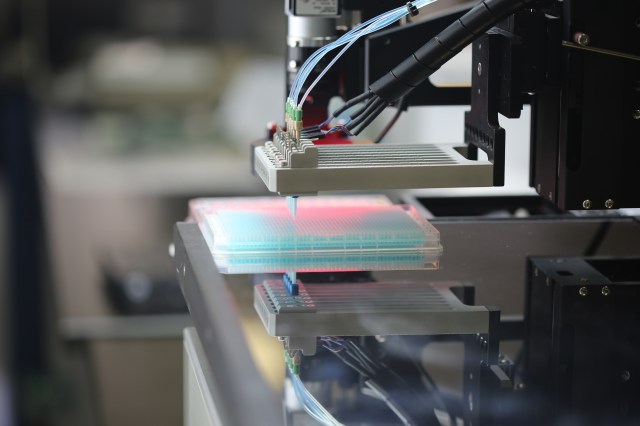

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Our Commitment to

Innovation

What good is an idea

if it remains an idea?

What good is an idea

if it remains an idea?

Try. Experiment. Iterate. Fail. Try again.

Change the world.

A Space to Create

Our dedicated team and showcase Innovation Center in Cambridge, Ontario, Canada, demonstrate our strong commitment to leading the way. Two additional innovation hubs have been established in Munich

Mission

Our Mission in the Innovation Center is simple: to support ATS in achieving the core value drivers by accelerating the transformation of new ideas into cutting-edge products, processes, and services, enabling us to deliver world-leading manufacturing solutions that set the industry standard.

Culture of Innovation

ATS has a strong history of innovation. Not only does each automation project bear the mark of this culture and skill, but it is also demonstrated through our creation of world-leading technology platforms such as SuperTrak CONVEYANCE™, SmartVision™, Symphoni™, and Illuminate™.

Overcoming Today’s Manufacturing Challenges

We understand the growing manufacturing challenges you’re facing today. That’s why our innovation focus provides a safe and dynamic space to accelerate the transformation of new ideas into cutting-edge products, processes, and services that position you for success.

Scaling Up Complexity for Diagnostics and Wearables in a Quick-to-Market Solution

Our customer, a global pharma company, is a producer of a cancer drug containing both a liquid and a powder that is delivered via syringe. Their existing assembly process was outdated, required staff in full PPE garb in cleanrooms, and was not Class A. They wanted an automated aseptic filling, handling and packaging line that included containment of APIs in the form of a liquid and a cytotoxic powder, and that was capable of increasing production capacity.

Ready To Think

Outside The Box?

Discover the Power of Innovation

Start your journey with us and push the boundaries of what’s possible.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube