Our customer, a large clinical diagnostic laboratory, was no stranger to lab automation. They had an existing line in their facility that had served their needs for many years; however, when it came time to scale up their sorting and aliquoting capacity, continuing with the status quo would have been both cost and footprint prohibitive.

ATS Life Sciences Systems (LSS) was challenged to develop a line capable of sorting up to 5000 samples per hour (>60% more capacity than their current line) without exceeding the existing footprint allotted for automation.

The Pain Points:

- Inefficient use of floor space: Multiple automated cells were connected with a complex network of conveyors, making accessibility and maintenance a challenge.

- Inefficient workflow: The existing workflow required a large amount of manual labour before the automation could accept samples as input, and then required further manual labour to manage the output of the machine.

- Complex software integration: The automation system was built from numerous suppliers each with their own approach to software development, meaning long-term maintenance and trouble shooting was becoming a problem.

The cumulative effect was a large amount of downtime and low OEE. Our LSS team reviewed the current equipment’s capabilities in great detail, taking note of the key pain points, before developing our concept.

It quickly became clear that, through clever implementation of ATS-developed technologies, we could develop a line that would meet and even exceed their requirements. ATS then developed a solution to address each pain point specifically.

The Solutions:

The resulting integrated automated laboratory system developed by LSS achieved the 5000 pph capacity at < 50% of the footprint of the existing sorting line, with a significant focus on long term OEE sustainability using best-in-class technologies and performance monitoring software.

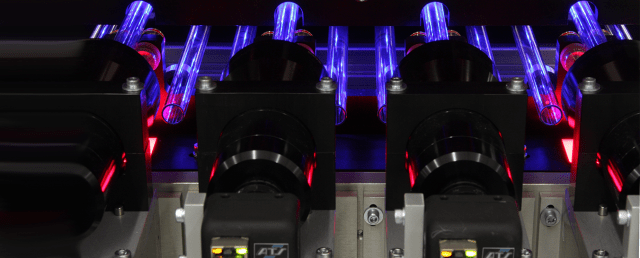

- Efficient use of floor space: Utilizing a single automation cell with SuperTrak CONVEYANCETM as the main indexing platform delivered superior performance with significantly less footprint. Through using the asynchronous controls, we were able to utilize the equipment to the fullest extent, increasing OEE and minimizing the number of tools necessary to achieve the target output.

- Efficient workflow: Utilizing our SmartVisionTM software and IlluminateTM Manufacturing Intelligence technology augmented the current workflow, allowing technicians to focus on key value-added tasks while the automation manages the scanning, sorting, and aliquoting (with full traceability). Additionally, the technology made the most of the data generated by the equipment to support regulatory compliance (including 21 CFR Part 11) and maintenance intervals (through predictive maintenance to detect abnormalities in equipment performance).

- Turnkey software integration: LSS managed the development and integration of the software solution, using industry proven technologies, to provide a seamless package that integrated into their existing IT systems.

Please contact an ATS representative to discuss your product needs: lifesciences@atsautomation.com

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube