- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Automated and fully robotic solutions

MATERIAL HANDLING

Introducing to and removing from automation the components, subassemblies, and finished product is a key aspect of efficient operation. In addition to customized solutions for trays or pallets, ATS Life Sciences also offers several standardized solutions

Specialization

ATS Clearliner™

A highly flexible tray or pallet handler ideal for trays or ISO/Euro pallet sizes from 400-1000 mm, with potential to integrate a conveyor belt or trolley for transfer

Labeling by ATS

A labelling system capable of handling a wide range of label forms and shapes, accommodating different product shapes and sizes

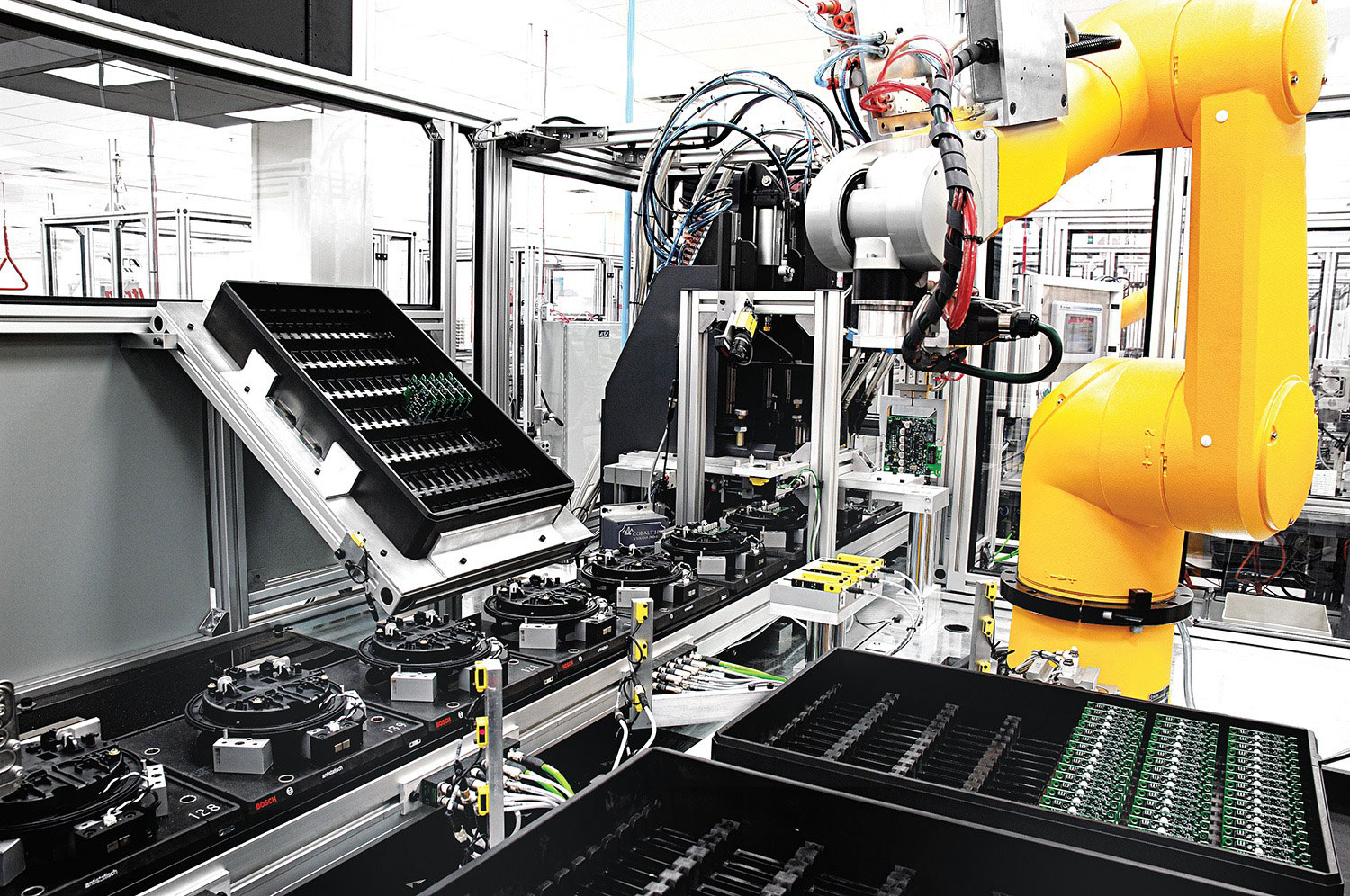

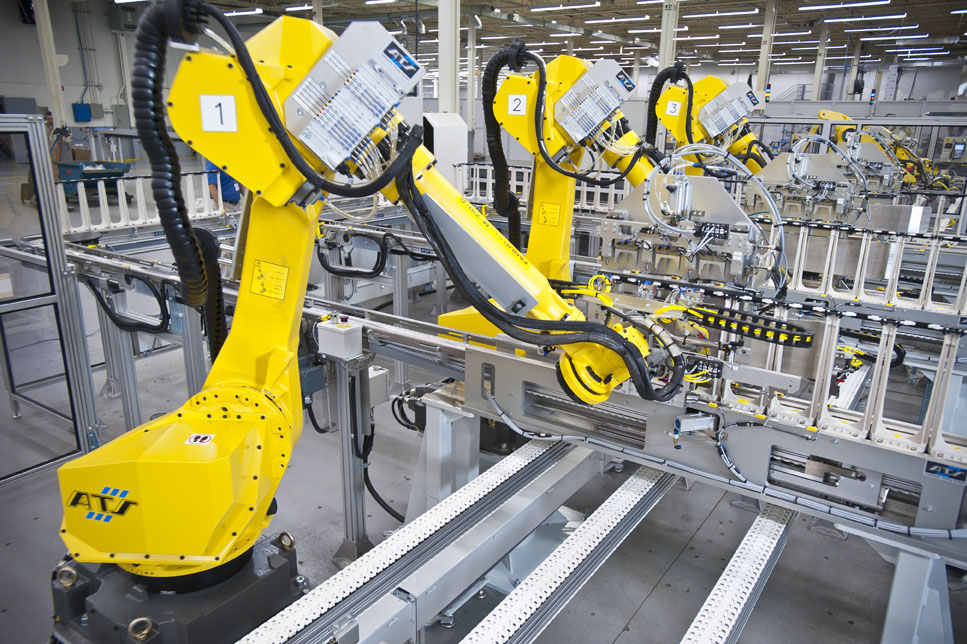

ATS Robotic Solutions

Turnkey robotic solutions that are highly flexible, scalable and innovative for trayhandling, palletizing, bin picking, assembly, packaging and more

Ready to make a move on your material handling needs?

We integrate material handling equipment for the movement of components, subassemblies, and finished product. Our material handling experts can discuss solutions for stacked trays, pallets, bulk components, and more.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube