We can optimize your plant or project with a variety of skills and processes to innovate and improve your production. From off-the-shelf and easily integrated to highly-customized and leading edge, we’re the partner to help you meet the need and achieve the goal.

Automated capture of inspection images, combined with classification of these same images by trained operators, sets the stage for developing machine learning algorithms. Inspections previously thought difficult to automate and validate may now be candidates for AI/ML

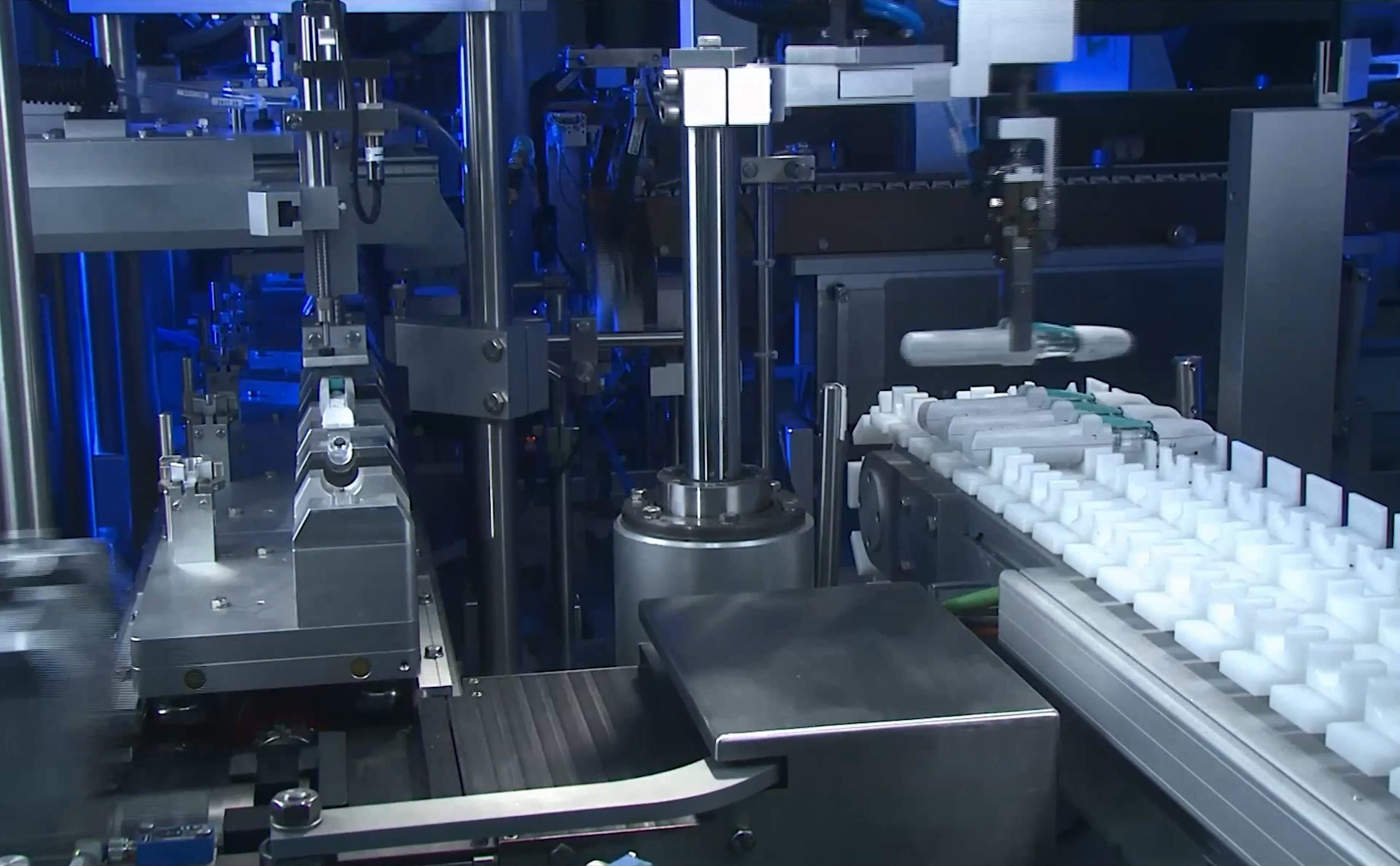

Automated, high-throughput, ultra-low volume dispensing from pico litres to nano litres, suitable for laboratories and production. Highly accurate, highly reproducible micro dosing vital to consistently high standards of production

Transfer system for cleanrooms – intelligently integrated, end-to-end automation to link handling system for downstream stages of assembly

Designs for reliable feeding and orientation of small or lightweight parts; particularly effective for safely transporting small, unstable parts that cannot be fed in bulk

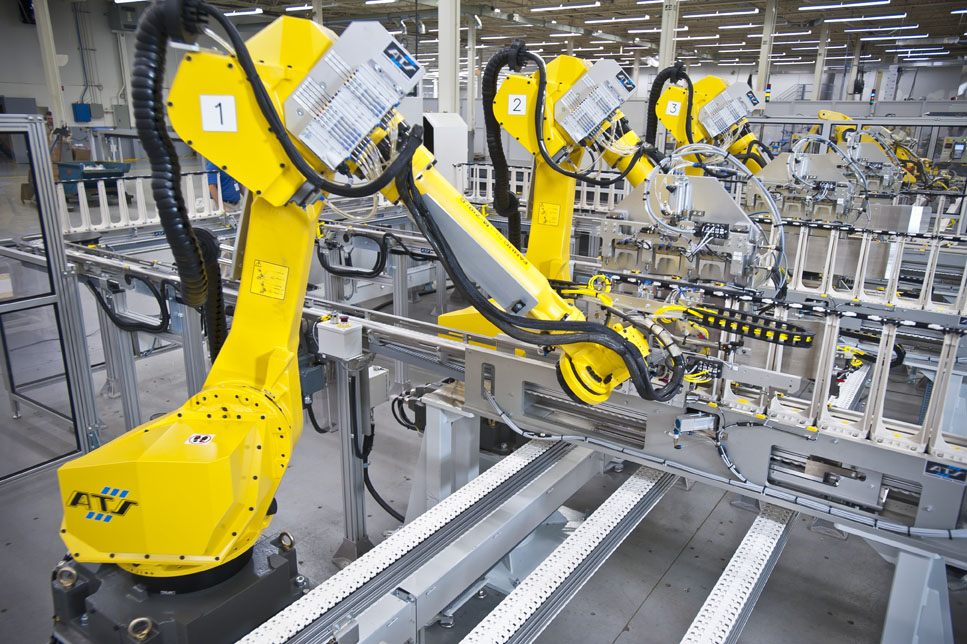

Custom, high-speed robot solutions provide flexibility for material handling. Designed to optimize system layout, part transfers happen within a multiple shot mold or between multiple machines

ATS has standard assembly machines for medical devices that require tube handling and joining (example tube sets)

Automated systems for de-reeling filter or foil materials through punch/die sets. Punching dies are interchangeable.

Custom specifications available to meet customer requirements.

We work hand in hand with the manufacturers of welding equipment to ensure seamless integration for this challenging process. Perfect weld seams and spots for products that function correctly, reliably and without leakage

Tubes are washed in a closed-cycle chamber, with up to 80% of water being returned. For purity, multistage filtering technology, capable of removing particles 0.2 μm in size. Can be followed by siliconization. Tubes are dried at a controlled temperature

LED and ultraviolet light-cured adhesives, able to tolerate steam sterilization, are ideal for consumable medical devices like tube sets, pen needles, autoinjectors, and glass syringes

Injection products, such as safety syringes and IV catheters, must be precision manufactured. Tip forming comprises precisely shaping the tube around the cannula. The correctly-oriented needle is directly transferred to the cannula hub for maximum precision

Mitigate the risk of microbiological contamination and product adulteration, while protecting the operator. Isolators and automated processing create a safe, aseptic environment that maintains separation between product and people

We use various printing technologies for marking on a variety of materials. Some methods also support multiple colors, and can guarantee the accurate positioning of the product required for perfect results.

Standard and custom solutions for manual or fully automatic tests; pressure decay, differential pressure, mass flow, helium Dual stage vacuum to evacuate the DUT and test chamber resulting in improved cycle times

Collected data and reports can be accessed in real time and used to fine tune operations and for electronic batch record purposes. In-process or finished product samples for quality control can be safely retrieved while maintaining complete traceability

Protective environments from classified rooms to RABS, isolators and aseptic automation that meet CGMP guidelines. Ergonomics, safety and performance with a combination of isolation technology and off-the-shelf process equipment integrated in a single unit

Finishing steps such as kitting, cartoning, and case packing are necessary before distribution, marketing, and end customer use. Our portfolio of solutions includes primary and secondary packaging

Vertical, horizontal and top loading cartoners and fully automatic box feeding for a huge range of packaging applications including bottles, tubes, blisters, jars, and pouches

Integrated equipment to package products into a sealed bag. Form film into a flexible package for a wide variety of products to be packed either separately or on a tray

FDA-validated process systems integrating sterilization equipment for devices and pharma products. Aseptic/sterile material handling with robotics, and packaging processes including autoclaves and gamma radiation sterilization systems

Vertical, horizontal and top loading cartoners and fully automatic box feeding for a huge range of packaging applications including bottles, tubes, blisters, jars, and pouches

Turnkey robotic solutions that are highly flexible, scalable and innovative for assembly, palletizing, packaging and more

Ready to discuss your life sciences project with an ATS specialist?

Contact us to set up a meeting for your project or process. Together we’ll find the right solution that generates the results you need.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube