- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Automated assembly for medical manufacturers

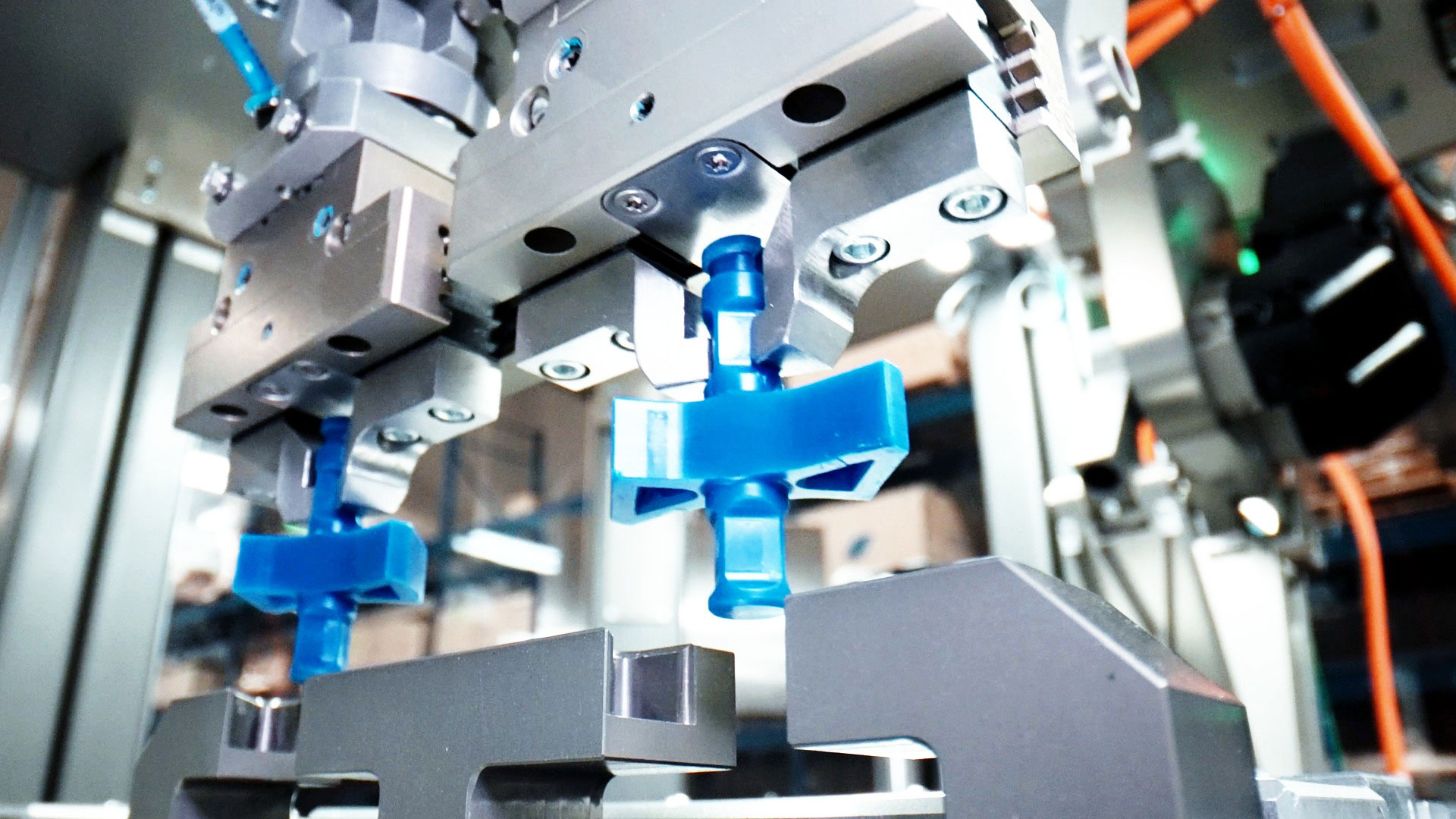

ASSEMBLY

ATS is an integrator of life science solutions to some of the world’s largest companies. Over more than 40 years we have developed both standardized platforms and customized options, so we can meet your product, process and production needs

Specialization

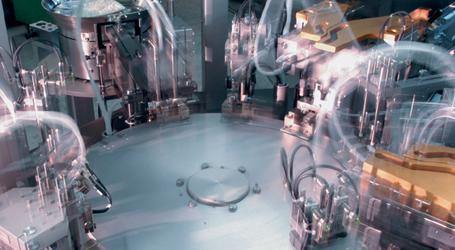

Symphoni™ Technology

An innovative digital assembly platform that delivers high-performance, flexibility and quality. With a high degree of standardization and a modular design, it delivers speed, versatility, AND precision without compromise

OmniTrak™ Assembly Platform

An assembly platform that combines the precision of cam-controlled workstations and the flexibility of linear motor-driven workpiece carriers, offering high flexibility, lower maintenance, and optimized footprint

Discovery™ Assembly Platform

A dial-based, cam-driven platform perfect for high throughput, synchronized processes, with high production performance and easy maintenance

Autoinjector Assembly

Final assembly systems for any common three-piece autoinjector with scalable output rates between 2 ppm and 120 ppm

Syringe Assembly

End-to-end and turn-key services for glass or plastic assembly and handling, including our patented LED UV adhesive curing

Jetwing™ Assembly (Platform)

A compact, modular, and customizable linear platform developed specifically for assembling items that need to go into production quickly or that require frequent design changes

ATS SwiftCell™

Standardized assembly and handling modules with greatest flexibility and scalability due to pick-and-choose grid dimensions

Ready to discuss your medical assembly project with an ATS specialist?

We can offer a standardized approach to meet your immediate need or put together a customized solution to address your longer-term automation plan.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube