Interpack 2026

May 7-13, 2026

Hall 15. Booth C20

Interpack 2026 is the world’s premier trade fair for processing and packaging technologies. It brings together thousands of international exhibitors and trade professionals to showcase innovations across the entire packaging value chain—including machinery, materials, process solutions, and services for sectors like food, beverages, pharmaceuticals, cosmetics, and industrial goods.

Together with our sister companies IWK and Comecer, ATS Life Sciences Systems will be showcasing our automation solutions for the life sciences industry, covering everything from low- to high-speed production and packaging, to support efficient and compliant manufacturing.“

Location

Messe Düsseldorf GmbH

Stockumer Kirchstraße 61

40474 Düsseldorf

Germany

Hall 15.

Booth C20

Event Times

May 7-13, 2026: 10:00am – 06:00 pm

Cohosts

BOOK A MEETING

Visit our booth in Hall 15.C20 and speak to our experts about how our innovative and turnkey automation solutions can help you get the edge in the market.

Symphoni™

Digital Assembly for Medical Devices

Digital assembly automation technology featuring an unmatched combination of speed, flexibility, and precision, delivering business value in a scalable, modular platform.

Enhanced servo-based motions and e-cams mean a single system can run multiple product lines 24/7 with 90% less retooling. SYMPHONI Technology’s compact design minimizes cleanroom space. Its standardization simplifies validation. Perfect for Life Sciences applications.

Benefits: High-speed, modular assembly for complex components

ATS SwiftCell™

The SwiftCell™ family of advanced standardized assembly modules is designed to meet the highest regulatory standards making us the go-to choice for leading medical devices manufacturers in the low volume sector.

Modular solution for medical device assembly and trayhandling which is adaptable, flexible, modular and cost-effective.

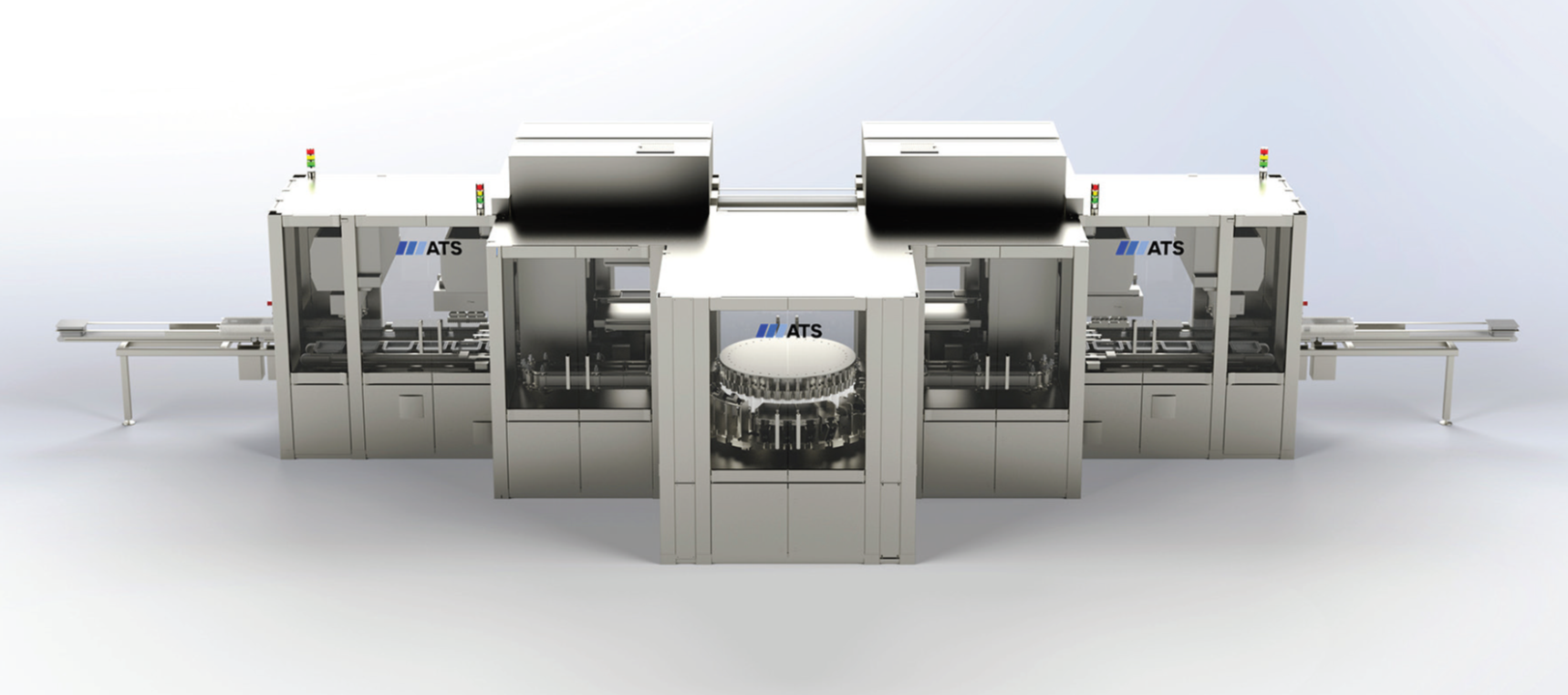

PharmaScan™ Lyo

Advanced inspection platforms for lyophilized products

This system offers near 100% accuracy at speeds of up to 425 ppm, processing approximately 60GB of images per minute. Designed for efficiency with a user-friendly interface, it handles multiple tub pitches, reducing changeovers. Built in North America and locally serviced, it’s recommended for lyophilized cakes and accommodates vials from 2R to 30R.

PharmaScan™ Liquid

Advanced inspection platforms for clear or colored liquids

This system meets FDA requirements for inspecting parenterals, handling up to 600 parts per minute with high-speed inspection that detects particles as small as 50 µm while reducing false rejects. It supports clear and colored liquids, as well as clear and colored containers, including glass and plastic, ensuring batch traceability and compliance with data handling regulations.

Messe Düsseldorf GmbH

Stockumer Kirchstraße, Germany

May 7-13, 2026

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube